中文词条原文链接(无法从中国内地访问):点击这里访问。

英文词条原文链接(无法从中国内地访问):点击这里访问。本文基于英文词条的线索,并补充部分来自中文词条的内容;在中英文内容完全相同的段落,使用原有的中文版本替换英文版本,其他部分英文词条则由辽观翻译。

辽观搬运时进行了必要的合规化处理,以使其能够在中国内地上传。

维基百科(Wikipedia)是美国维基媒体基金会的互联网百科项目(点击这里了解更多),其内容可能受到立场、信息来源等因素影响,请客观看待。正文内容不代表译者观点。

辽观提供的翻译仅供参考。文中可能包含无法从中国大陆访问的链接。

文中可能包含无法从中国内地访问的链接。 辽观所搬运的词条与原维基百科词条同样遵循CC-BY-SA 4.0协议,在符合协议要求的情况下您可以免费使用其内容(包括商用)。图片和视频可能遵循不同的协议,我们会在文中具体位置标明;协议文本请点击这里访问。

Not to be confused with propfan or turboprop.

不要与螺旋桨风扇或涡轮螺旋桨发动机混淆。

This article is about the mechanism used in jets. For the turbo like air pressure blower sometimes misnamed Turbo fan, see Centrifugal fan.

本文介绍的是喷气机中使用的机制。 对于涡轮式空气压力鼓风机有时被错误命名为“涡轮风扇”,请参阅“离心风扇”。

目录

0. 概述

辽观注:此标题是我们在搬运、整合过程中添加的。

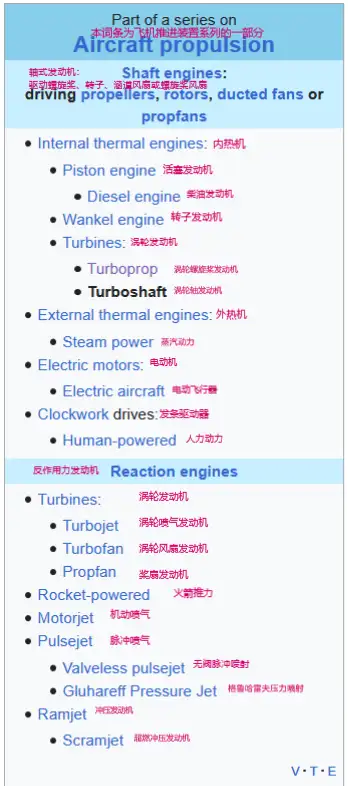

涡轮风扇发动机(英语:Turbofan Engine,亦称涡扇发动机或者内外函喷气发动机)是一种燃气涡轮式航空发动机,主要特点是其首级扇叶的面积较涡轮喷气发动机大上许多。经过涡轮喷气发动机的空气通道称为内涵道,空气在喷气发动机燃烧后获得机械能,外侧的空气通道称为外涵道,由内含的涡轮驱动首级增压扇叶推动空气,增压扇叶同时具有螺旋桨和压缩空气的作用,能将部分吸入的空气通过喷气发动机的外围提供直接推力,推力即由内外涵道共同产生。[1][2]可同时具有涡轮螺旋桨与涡轮喷气发动机的推力供给。

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word “turbofan” is a combination of the preceding generation engine technology of the turbojet, and a reference to the additional fan stage added. It consists of a gas turbine engine which achieves mechanical energy from combustion,[1] and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

参考译文:涡轮风扇发动机或风扇喷气发动机是一种广泛用于飞机推进的吸气式喷气发动机。 “涡轮风扇”一词是上一代涡轮喷气发动机技术的组合,并引用了附加的风扇级。 它由一个从燃烧中获得机械能的燃气涡轮发动机[1]和一个利用燃气涡轮机的机械能迫使空气向后推动的涵道风扇组成。 因此,涡轮喷气发动机吸入的所有空气都会穿过燃烧室和涡轮机,而在涡轮风扇发动机中,部分空气会绕过这些部件。 因此,涡轮风扇发动机可以被认为是用于驱动涵道风扇的涡轮喷气发动机,两者都有助于推力。

涡轮风扇发动机外观上似乎是更粗的发动机,实际上只有中心是喷气发动机,其他全是扇风推进,因为并非只依靠涡轮喷气直接燃油燃烧出高压空气提供推力,所以单位推力小时耗油率比纯涡轮喷气佳,但螺旋扇叶速度越快的推力重量比耗损功率较大,比较纯涡轮喷气,超音速飞行时其受到附面层影响使其低气压高空与超音速下推力重量不佳。于是乎,涡扇发动机最适合飞行速度为每小时400至2,000公里时使用,故此现在多数的喷气机发动机都是采用涡扇发动机作为动力来源。

The ratio of the mass-flow of air bypassing the engine core to the mass-flow of air passing through the core is referred to as the bypass ratio. The engine produces thrust through a combination of these two portions working together; engines that use more jet thrust relative to fan thrust are known as low-bypass turbofans, conversely those that have considerably more fan thrust than jet thrust are known as high-bypass. Most commercial aviation jet engines in use today are of the high-bypass type,[2][3] and most modern military fighter engines are low-bypass.[4][5] Afterburners are used on low-bypass turbofan engines with bypass and core mixing before the afterburner.

参考译文:绕过发动机核心的空气质量流量与通过核心的空气质量流量之比称为涵道比。 发动机通过这两个部分一起工作来产生推力; 相对于风扇推力使用更多喷射推力的发动机被称为低涵道比涡轮风扇发动机,相反,那些风扇推力比喷射推力大得多的发动机被称为高涵道比涡轮风扇发动机。 当今使用的大多数商用航空喷气发动机都是高涵道比类型,[2][3],大多数现代军用战斗机发动机都是低涵道比发动机。[4][5] 加力燃烧室用于低旁通涡轮风扇发动机,在加力燃烧室之前具有旁路和核心混合。

涡轮风扇发动机的涵道比是单位时间内不经过燃烧室的空气质量,与通过燃烧室的空气质量的比例。涵道比为零的涡扇发动机即是涡轮喷气发动机,早期的涡扇发动机和现代战斗机使用的涡扇发动机涵道比都较低,例如世界上第一款实用涡扇发动机,罗尔斯·罗伊斯的康威型涵道比只有0.3,现代多数民用飞机为了省油,发动机的涵道比越来越大,通常都在5以上,跟使用螺旋桨飞行其实是差不多。涵道比高的涡轮风扇发动机耗油较少,但推力却与涡轮喷气发动机相当,且运转时还宁静得多。

至于战斗机使用低涵道比发动机,主要是因为截面积与常用飞行速度与民用飞机不同。高涵道比的发动机截面积过大在超音速的时候阻力过大,另外在超音速的状况下效率也会比纯涡轮喷气甚至于低涵道比设计还低,所以战斗机皆使用低涵道比发动机(涵道比皆低于1)。只在超音速飞行的协和式客机,因为长时间处于超音速状态,为了提升效率与降低成本,就是使用纯涡轮喷气而无涵道比的发动机,是少数真正利用喷气飞行的飞机。

Modern turbofans have either a large single-stage fan or a smaller fan with several stages. An early configuration combined a low-pressure turbine and fan in a single rear-mounted unit.

参考译文:现代涡轮风扇发动机要么具有大型单级风扇,要么具有较小的多级风扇。 早期的配置将低压涡轮机和风扇组合在一个后置单元中。

1. 原理 | Principles

主要组成部分

- 进气道

- 风扇总成

- 低压压气机(Low pressure compressor)

- 高压压气机(High pressure compressor)

- 燃烧室

- 高压涡轮(High pressure turbine)

- 低压涡轮(Low pressure turbine)

- 加力燃烧室

- 喷管

The turbofan was invented to improve the fuel consumption of the turbojet. It achieves this by pushing more air, thus increasing the mass and lowering the speed of the propelling jet compared to that of the turbojet. This is done mechanically by adding a ducted fan rather than using viscous forces[6] by adding an ejector, as first envisaged by Whittle.[7]

参考译文:涡扇发动机的发明是为了改善涡喷发动机的燃油消耗。它通过增加推进气流的质量,从而降低推进喷流的速度,以此达到节省燃料的目的。与涡喷发动机相比,涡扇发动机通过增加一个内缘风扇来实现这一点,而不是通过增加喷射器来利用黏性力[6],这是由Whittle首先设想的方式[7]。

Frank Whittle envisioned flight speeds of 500 mph in his March 1936 UK patent 471,368 “Improvements relating to the propulsion of aircraft”, in which he describes the principles behind the turbofan,[8] although not called as such at that time. While the turbojet uses the gas from its thermodynamic cycle as its propelling jet, for aircraft speeds below 500 mph there are two penalties to this design which are addressed by the turbofan.

参考译文:弗兰克·惠特尔在他1936年3月的英国专利471,368《改进有关飞机推进的方法》中设想了500英里每小时的飞行速度,并在其中描述了涡扇发动机背后的原理[8],尽管当时还没有以这样的名称。尽管涡喷发动机使用其热力循环中的气体作为推进喷流,但在飞行速度低于500英里每小时时,这种设计存在两个问题,而涡扇发动机解决了这些问题。

Firstly, energy is wasted as the propelling jet is going much faster rearwards than the aircraft is going forwards, leaving a very fast wake. This wake contains kinetic energy that reflects the fuel used to produce it, rather than the fuel used to move the aircraft forwards. A turbofan harvests that wasted velocity and uses it to power a ducted fan that blows air in bypass channels around the rest of the turbine. This reduces the speed of the propelling jet while pushing more air, and thus more mass.

参考译文:首先,由于推进喷流向后的速度远远快于飞机向前的速度,能量被浪费掉了,形成了一个非常快速的尾流。这个尾流包含了用于产生它的燃料所反映的动能,而不是用于推动飞机向前的燃料。涡扇发动机利用这种被浪费的速度,用来驱动一个带导流风扇的旁通通道,将空气绕过涡轮的其余部分吹出。这降低了推进喷流的速度同时也推动更多的空气,从而增加了质量。

The other penalty is that combustion is less efficient at lower speeds. Any action to reduce the fuel consumption of the engine by increasing its pressure ratio or turbine temperature to achieve better combustion causes a corresponding increase in pressure and temperature in the exhaust duct which in turn cause a higher gas speed from the propelling nozzle (and higher KE and wasted fuel). Although the engine would use less fuel to produce a pound of thrust, more fuel is wasted in the faster propelling jet. In other words, the independence of thermal and propulsive efficiencies, as exists with the piston engine/propeller combination which preceded the turbojet, is lost.[9] In contrast, Roth[10] considers regaining this independence the single most important feature of the turbofan which allows specific thrust to be chosen independently of the gas generator cycle.

参考译文:另一个问题是,在较低的速度下,燃烧效率较低。为了通过增加涡扇发动机的压力比或涡轮温度以实现更好的燃烧来减少燃料消耗,导致排气管中的压力和温度相应增加,从而导致推进喷嘴中的气体速度增加(以及动能和燃料浪费增加)。尽管发动机每产生一磅的推力所需的燃料更少,但在速度更快的推进喷流中浪费更多的燃料。换句话说,与之前的活塞发动机/螺旋桨组合相比(这种组合在涡喷发动机之前存在),热效率和推力效率是独立的,这种独立性已经丧失[9]。相比之下,Roth认为,恢复这种独立性是涡扇发动机最重要的特点,它允许特定的推力独立于气体发生器循环的选择[10]。

The working substance of the thermodynamic cycle is the only mass accelerated to produce thrust in a turbojet which is a serious limitation (high fuel consumption) for aircraft speeds below supersonic. For subsonic flight speeds the speed of the propelling jet has to be reduced because there is a price to be paid in producing the thrust. The energy required to accelerate the gas inside the engine (increase in kinetic energy) is expended in two ways, by producing a change in momentum ( ie a force), and a wake which is an unavoidable consequence of producing thrust by an airbreathing engine[11] (or propeller). The wake velocity, and fuel burned to produce it, can be reduced and the required thrust still maintained by increasing the mass accelerated. A turbofan does this by transferring energy available inside the engine, from the gas generator, to a ducted fan which produces a second, additional mass of accelerated air.

参考译文:涡喷发动机的热力循环中的工作物质是唯一用于产生推力的加速质量,这对于亚音速的飞行速度来说是一个严重的限制(燃料消耗高)。对于亚音速飞行速度,推进喷流的速度必须降低,因为产生推力是需要付出代价的。加速发动机内部气体(动能增加)所需的能量以两种方式消耗,一种是产生动量变化(即力),另一种是产生尾流,这是通过空气呼吸发动机(或螺旋桨)产生推力的不可避免的后果[11]。尾流的速度和产生尾流所燃烧的燃料可以通过增加加速质量来减少,并仍然保持所需的推力。涡扇发动机通过将发动机内的能量从气体发生器转移到带导流风扇上,产生了第二个额外的加速空气质量,实现了这一点。

The transfer of energy from the core to bypass air results in lower pressure and temperature gas entering the core nozzle (lower exhaust velocity) and fan-produced temperature and pressure entering the fan nozzle. The amount of energy transferred depends on how much pressure rise the fan is designed to produce (fan pressure ratio). The best energy exchange (lowest fuel consumption) between the two flows, and how the jet velocities compare, depends on how efficiently the transfer takes place which depends on the losses in the fan-turbine and fan.[12]

参考译文:将能量从核心传输到旁通空气中导致进入核心喷嘴的气体的压力和温度降低(排气速度降低),而进入风扇喷嘴的气体的温度和压力由风扇产生。传输的能量量取决于风扇设计要产生多少压力增升(风扇压力比)。两个流之间的能量交换(燃料消耗最低)以及喷气速度的比较取决于传输的效率,这又取决于风扇-涡轮和风扇中的损失[12]。

The fan flow has lower exhaust velocity, giving much more thrust per unit energy (lower specific thrust). Both airstreams contribute to the gross thrust of the engine. The additional air for the bypass stream increases the ram drag in the air intake stream-tube, but there is still a significant increase in net thrust. The overall effective exhaust velocity of the two exhaust jets can be made closer to a normal subsonic aircraft’s flight speed and gets closer to the ideal Froude efficiency. A turbofan accelerates a larger mass of air more slowly, compared to a turbojet which accelerates a smaller amount more quickly, which is a less efficient way to generate the same thrust (see the efficiency section below).

参考译文:风扇流具有较低的排气速度,每单位能量产生更多的推力(比冲较低)。两个气流都对发动机的总推力做出贡献。旁通流的额外空气增加了进气流管中的冲压阻力,但净推力仍然显著增加。两个排气喷流的整体有效排气速度可以接近正常亚音速飞机的飞行速度,并接近理想的弗劳德效率。涡喷发动机以较慢的速度加速更大质量的空气,而涡喷发动机以较快的速度加速较小质量的空气,这是一种产生相同推力的效率较低的方式(请参阅下面的效率部分)。

The ratio of the mass-flow of air bypassing the engine core compared to the mass-flow of air passing through the core is referred to as the bypass ratio. Engines with more jet thrust relative to fan thrust are known as low-bypass turbofans, those that have considerably more fan thrust than jet thrust are known as high-bypass. Most commercial aviation jet engines in use today are high-bypass,[2][3] and most modern fighter engines are low-bypass.[4][5] Afterburners are used on low-bypass turbofans on combat aircraft.

参考译文:旁通比是旁通发动机核心通过的空气质量流量与旁通发动机核心通过的空气质量流量比。相对于风扇推力,喷气推力更大的发动机称为低旁通涡喷发动机,而相对于喷气推力,风扇推力更大的发动机则称为高旁通喷发动机。目前使用的大多数商用航空喷气发动机都是高旁通涡喷发动机,而大多数现代战斗机发动机则是低旁通涡喷发动机。低旁通涡喷发动机上的加力燃烧器用于战斗机上。

1.1 涵道比/旁通比 | Bypass ratio

Main article: Bypass ratio

主条目:涵道比/旁通比

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core.[13] A bypass ratio of 6, for example, means that 6 times more air passes through the bypass duct than the amount that passes through the combustion chamber.

参考译文:旁通比(BPR)是涡喷发动机中旁通流的质量流量与进入核心的质量流量之间的比值[13]。例如,旁通比为6意味着旁通管中通过的空气量是通过燃烧室通过的空气量的6倍。

Turbofan engines are usually described in terms of BPR, which together with overall pressure ratio, turbine inlet temperature and fan pressure ratio are important design parameters. In addition BPR is quoted for turboprop and unducted fan installations because their high propulsive efficiency gives them the overall efficiency characteristics of very high bypass turbofans. This allows them to be shown together with turbofans on plots which show trends of reducing specific fuel consumption (SFC) with increasing BPR.[14] BPR can also be quoted for lift fan installations where the fan airflow is remote from the engine and doesn’t flow past the engine core.

参考译文:涡扇发动机通常以旁通比、总压比、涡轮进口温度和风扇压比等重要设计参数来描述。此外,旁通比也适用于涡桨和非导流风扇装置,因为它们具有非常高的推力效率,可以具备非常高的旁通涡喷发动机的整体效率特性。这使得它们可以与涡喷发动机一起显示在显示随着旁通比增加而降低比油耗的趋势的图表上[14]。对于升力风扇装置,旁通比也可以作为引用,其中风扇气流与发动机相隔一段距离,并不经过发动机核心。

Considering a constant core (ie fixed pressure ratio and turbine inlet temperature), core and bypass jet velocities equal and a particular flight condition (ie Mach number and altitude) the fuel consumption per lb of thrust (sfc) decreases with increase in BPR. At the same time gross and net thrusts increase, but by different amounts.[15] There is considerable potential for reducing fuel consumption for the same core cycle by increasing BPR.This is achieved because of the reduction in pounds of thrust per lb/sec of airflow (specific thrust) and the resultant reduction in lost kinetic energy in the jets (increase in propulsive efficiency).[16]

参考译文:在核心恒定(即压力比和涡轮进口温度固定)、核心和旁通喷流速度相等以及特定的飞行条件(即马赫数和高度)下,每磅推力的燃油消耗(比油耗)随着旁通比的增加而减少。同时,总推力和净推力都会增加,但增加的幅度不同[15]。通过增加旁通比,可以大幅降低相同核心循环的燃油消耗。这是因为每秒空气流量的磅推力(比推力)减少,喷流中失去的动能减少(推力效率增加)[16]。

If all the gas power from a gas turbine is converted to kinetic energy in a propelling nozzle, the aircraft is best suited to high supersonic speeds. If it is all transferred to a separate big mass of air with low kinetic energy, the aircraft is best suited to zero speed (hovering). For speeds in between, the gas power is shared between a separate airstream and the gas turbine’s own nozzle flow in a proportion which gives the aircraft performance required. The trade off between mass flow and velocity is also seen with propellers and helicopter rotors by comparing disc loading and power loading.[17] For example, the same helicopter weight can be supported by a high power engine and small diameter rotor or, for less fuel, a lower power engine and bigger rotor with lower velocity through the rotor.

参考译文:如果将燃气涡轮中的所有气体功率转化为推进喷管中的动能,飞机最适合高超音速飞行。如果将所有气体功率转移到具有低动能的独立大气团中,飞机最适合零速(悬停)。对于中间速度,气体功率在独立的气流和燃气涡轮的喷管流之间按比例共享,以获得所需的飞机性能。通过比较盘面负载和功率负载,可以看到推进器和直升机旋翼的质量流量和速度之间的权衡[17]。例如,相同的直升机重量可以通过高功率发动机和小直径旋翼支撑,也可以通过功率较低的发动机和更大直径、旋翼速度较低的旋翼来支撑,以减少燃料消耗。

Bypass usually refers to transferring gas power from a gas turbine to a bypass stream of air to reduce fuel consumption and jet noise. Alternatively, there may be a requirement for an afterburning engine where the sole requirement for bypass is to provide cooling air. This sets the lower limit for BPR and these engines have been called “leaky” or continuous bleed turbojets[18] (General Electric YJ-101 BPR 0.25) and low BPR turbojets[19] (Pratt & Whitney PW1120). Low BPR (0.2) has also been used to provide surge margin as well as afterburner cooling for the Pratt & Whitney J58.[20]

参考译文:旁通通常指将燃气涡轮中的气体功率转移到旁通气流中,以减少燃料消耗和喷气噪音。另外,可能还有对加力发动机的需求,其旁通的唯一要求是提供冷却空气。这为旁通比设定了下限,这些发动机被称为“泄漏”或连续泄漏涡气喷气发动机[18](通用电气YJ-101,旁通比为0.25)和低旁通比喷气发动机[19](普惠PW1120)。低旁通比(0.2)也用于为普惠J58提供涡前裕度以及加力燃烧室冷却[20]。

1.2 能效 | Efficiency

Propeller engines are most efficient for low speeds, turbojet engines for high speeds, and turbofan engines between the two. Turbofans are the most efficient engines in the range of speeds from about 500 to 1,000 km/h (270 to 540 kn; 310 to 620 mph), the speed at which most commercial aircraft operate.[21][22]

参考译文:螺旋桨发动机在低速下效率最高,涡喷发动机在高速下效率最高,而涡扇发动机则介于两者之间。涡扇发动机在大约500到1,000公里/小时(270到540节;310到620英里/小时)的速度范围内是最高效的发动机,这也是大多数商用飞机运行的速度[21][22]。

In a turbojet (zero-bypass) engine, the high temperature and high pressure exhaust gas is accelerated when it undergoes expansion through a propelling nozzle and produces all the thrust. The compressor absorbs the mechanical power produced by the turbine. In a bypass design, extra turbines drive a ducted fan that accelerates air rearward from the front of the engine. In a high-bypass design, the ducted fan and nozzle produce most of the thrust. Turbofans are closely related to turboprops in principle because both transfer some of the gas turbine’s gas power, using extra machinery, to a bypass stream leaving less for the hot nozzle to convert to kinetic energy. Turbofans represent an intermediate stage between turbojets, which derive all their thrust from exhaust gases, and turbo-props which derive minimal thrust from exhaust gases (typically 10% or less).[23] Extracting shaft power and transferring it to a bypass stream introduces extra losses which are more than made up by the improved propulsive efficiency. The turboprop at its best flight speed gives significant fuel savings over a turbojet even though an extra turbine, a gearbox and a propeller are added to the turbojet’s low-loss propelling nozzle.[24] The turbofan has additional losses from its greater number of compressor stages/blades, fan and bypass duct.[clarification needed]

参考译文:在涡喷(零旁通比)发动机中,高温高压的排气经过喷射喷嘴膨胀时加速,并产生所有的推力。压气机吸收涡轮产生的机械功率。在旁通设计中,额外的涡轮驱动一个导流风扇,从发动机前部向后加速空气。在高旁通比设计中,导流风扇和喷嘴产生大部分的推力。涡扇发动机与涡轴螺旋桨发动机在原理上密切相关,因为两者都使用额外的机械装置将部分燃气涡轮的功率转移到旁通气流中,从而减少了热喷嘴将其转化为动能的能量。涡扇发动机处于涡喷发动机完全依靠排气气体产生推力和涡轴螺旋桨发动机仅在少量程度上依靠排气气体产生推力之间的中间阶段[23]。提取轴功并将其转移到旁通气流中会引入额外的损失,但这些损失被提高的推进效率所弥补。在最佳飞行速度下,涡轴螺旋桨发动机的燃料节约明显优于涡喷发动机,即使涡喷发动机的低损失喷射喷嘴需要增加额外的涡轮、齿轮箱和螺旋桨[24]。涡扇发动机由于其较多的压气机级数/叶片、风扇和旁通导流管而产生额外的损失[需要澄清]。

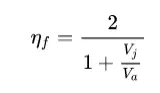

Froude, or propulsive, efficiency can be defined as:

参考译文:弗劳德效率(Froude efficiency),又称推进效率,可以定义为:

where:

在这里:

- Vj = thrust equivalent jet velocity

Vj代表推力等效喷流速度。 - Va = aircraft velocity

Va代表飞机速度。

1.3 推力 | Thrust

While a turbojet engine uses all of the engine’s output to produce thrust in the form of a hot high-velocity exhaust gas jet, a turbofan’s cool low-velocity bypass air yields between 30% and 70% of the total thrust produced by a turbofan system.[25]

参考译文:当涡喷发动机将其所有输出用于产生高速热排气喷流形式的推力时,涡扇发动机的冷低速副流气体产生了涡扇系统总推力的30%至70%。

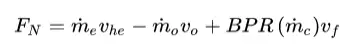

The thrust (FN) generated by a turbofan depends on the effective exhaust velocity of the total exhaust, as with any jet engine, but because two exhaust jets are present the thrust equation can be expanded as:[26]

参考译文:涡扇发动机产生的推力(FN)取决于总排气的有效排气速度,就像任何喷气发动机一样,但由于存在两个排气喷流,推力方程可以扩展为:

where:

在这里:

- me = the mass rate of hot combustion exhaust flow from the core engine

me代表从核心发动机排出的燃烧热排气流的质量流率。 - mo = the mass rate of total air flow entering the turbofan = •mc + •mf

mo代表进入涡扇发动机的总空气流量的质量流率,即mo = mc + mf,其中mc表示从核心发动机进入的空气质量流率,mf表示从风扇进入的空气质量流率。 - mc = the mass rate of intake air that flows to the core engine

mc表流向核心发动机的进气空气的质量流量。 - mf = the mass rate of intake air that bypasses the core engine

mf代表绕过核心发动机的进气空气的质量流量。 - vf = the velocity of the air flow bypassed around the core engine

vf表示绕过核心发动机的空气流动的速度。 - vhe = the velocity of the hot exhaust gas from the core engine

vhe代表核心发动机排出的热排气气体的速度。 - vo = the velocity of the total air intake = the true airspeed of the aircraft

vo代表总进气速度,也可以理解为飞机的真空速。 - BPR = bypass ratio

旁通比(涵道比)

1.4 Nozzles | 喷嘴

The cold duct and core duct’s nozzle systems are relatively complex due to the use of two separate exhaust flows. In high bypass engines, the fan is situated in a short duct near the front of the engine and typically has a convergent cold nozzle, with the tail of the duct forming a low pressure ratio nozzle that under normal conditions will choke creating supersonic flow patterns around the core[citation needed]. The core nozzle is more conventional, but generates less of the thrust, and depending on design choices, such as noise considerations, may conceivably not choke.[27] In low bypass engines the two flows may combine within the ducts, and share a common nozzle, which can be fitted with afterburner.

参考译文:由于使用了两个单独的排气流,冷气道和核心气道的喷管系统相对复杂。在高副推发动机中,风扇位于发动机前部附近的一个短气道内,通常具有收敛的冷喷管,而气道尾部形成一个低压比喷管,在正常情况下会窒息,形成绕过核心的超音速流动模式[需要引证]。核心喷管比较传统,但产生的推力较小,根据设计选择,如噪音考虑,可能不会窒息[27]。在低副推发动机中,两个流动可以在气道内合并,并共用一个喷管,该喷管可以安装加力燃烧器。

1.5 Noise | 噪音

Most of the air flow through a high-bypass turbofan is lower-velocity bypass flow: even when combined with the much-higher-velocity engine exhaust, the average exhaust velocity is considerably lower than in a pure turbojet. Turbojet engine noise is predominately jet noise from the high exhaust velocity. Therefore, turbofan engines are significantly quieter than a pure-jet of the same thrust, and jet noise is no longer the predominant source.[28] Turbofan engine noise propagates both upstream via the inlet and downstream via the primary nozzle and the by-pass duct. Other noise sources are the fan, compressor and turbine.[29]

参考译文:高副推涡扇发动机中的大部分空气流动是低速绕流:即使与高速发动机排气相结合,平均排气速度远低于纯涡喷发动机。涡喷发动机的噪音主要来自高速排气的喷气噪音。因此,与相同推力的纯喷气发动机相比,涡扇发动机的噪音明显较低,喷气噪音不再是主要的噪音源[28]。涡扇发动机的噪音通过进气口向上游传播,并通过主喷管和旁通管向下游传播。其他噪音源包括风扇、压气机和涡轮[29]。

Modern commercial aircraft employ high-bypass-ratio (HBPR) engines with separate flow, non-mixing, short-duct exhaust systems. Their noise is due to the speed, temperature, and pressure of the exhaust jet, especially during high-thrust conditions, such as those required for takeoff. The primary source of jet noise is the turbulent mixing of shear layers in the engine’s exhaust. These shear layers contain instabilities that lead to highly turbulent vortices that generate the pressure fluctuations responsible for sound. To reduce the noise associated with jet flow, the aerospace industry has sought to disrupt shear layer turbulence and reduce the overall noise produced.[citation needed]

参考译文:现代商用飞机采用高副推比(HBPR)发动机,具有单独流动、非混合、短气道排气系统。它们的噪音是由排气喷流的速度、温度和压力引起的,特别是在需要高推力的情况下,比如起飞时。喷气噪音的主要来源是发动机排气中的剪切层的湍流混合。这些剪切层包含不稳定性,导致高度湍流的涡旋产生压力波动,从而产生声音。为了减少与喷流相关的噪音,航空航天工业一直在寻求破坏剪切层湍流并减少总体噪音的方法[需要引证]。

Fan noise may come from the interaction of the fan-blade wakes with the pressure field of the downstream fan-exit stator vanes. It may be minimized by adequate axial spacing between blade trailing edge and stator entrance.[30] At high engine speeds, as at takeoff, shock waves from the supersonic fan tips, because of their unequal nature, produce noise of a discordant nature known as “buzz saw” noise.[31][32]

参考译文:风扇噪音可能来自风扇叶片尾迹与下游风扇出口定向叶片的压力场的相互作用。通过在叶片尾缘和定向叶片进口之间保持足够的轴向间距,可以将其最小化[30]。在高转速下,比如起飞时,由于超音速风扇叶尖的不均匀性,会产生不和谐的噪音,被称为“锯齿噪音”[31][32]。

All modern turbofan engines have acoustic liners in the nacelle to damp their noise. They extend as much as possible to cover the largest surface area. The acoustic performance of the engine can be experimentally evaluated by means of ground tests[33] or in dedicated experimental test rigs.[34]

参考译文:所有现代涡扇发动机都在发动机舱壳中装有声学衬板,用于减振噪音。它们尽可能地延伸以覆盖最大的表面积。发动机的声学性能可以通过地面试验[33]或专门的实验测试装置进行实验评估[34]。

In the aerospace industry, chevrons are the “saw-tooth” patterns on the trailing edges of some jet engine nozzles[35] that are used for noise reduction. The shaped edges smooth the mixing of hot air from the engine core and cooler air flowing through the engine fan, which reduces noise-creating turbulence.[35] Chevrons were developed by GE under a NASA contract.[35][36] Some notable examples of such designs are Boeing 787 and Boeing 747-8 – on the Rolls-Royce Trent 1000 and General Electric GEnx engines.[37]

参考译文:在航空航天工业中,切弗朗是一些喷气发动机喷口尾迹的“锯齿”图案[35],用于降噪。这些形状的边缘平滑了来自发动机核心的热空气和通过发动机风扇流动的冷气流的混合,从而减少了产生噪音的湍流[35]。切弗朗是由通用电气公司在NASA的合同下开发的[35][36]。一些著名的设计示例包括波音787和波音747-8上的劳斯莱斯特伦1000和通用电气GEnx发动机[37]。

2. 历史 | History

Early turbojet engines were not very fuel-efficient because their overall pressure ratio and turbine inlet temperature were severely limited by the technology and materials available at the time.

参考译文:早期的涡轮喷气发动机燃油效率不高,因为它们的总压力比和涡轮入口温度受到当时可用的技术和材料的严重限制。

The first turbofan engine, which was only run on a test bed, was the German Daimler-Benz DB 670, designated the 109-007 by the Nazi Ministry of Aviation, with a first run date of 27 May 1943, after the testing of the turbomachinery using an electric motor, which had been undertaken on 1 April 1943.[38] Development of the engine was abandoned with its problems unsolved, as the war situation worsened for Germany.

参考译文:第一个涡扇发动机是德国戴姆勒-奔驰DB 670,在纳粹航空部门被称为109-007,于1943年5月27日首次运行,在此之前,该发动机的涡轮机械装置已于1943年4月1日使用电动机进行了测试[38]。由于战争对德国的情况日益恶化,该发动机的开发被中止,并且其问题未能解决。

Later in 1943, the British ground tested the Metrovick F.3[39] turbofan, which used the Metrovick F.2 turbojet as a gas generator with the exhaust discharging into a close-coupled aft-fan module comprising a contra-rotating LP turbine system driving two co-axial contra-rotating fans.[40]

参考译文:在1943年晚些时候,英国对Metrovick F.3进行了地面测试[39],该发动机使用Metrovick F.2涡喷作为气体发生器,排气口排放到一个紧密耦合的后风扇模块中,该模块由一个逆转的低压涡轮系统驱动两个同轴逆转的风扇[40]。

Improved materials, and the introduction of twin compressors, such as in the Bristol Olympus,[41] and Pratt & Whitney JT3C engines, increased the overall pressure ratio and thus the thermodynamic efficiency of engines. They also had poor propulsive efficiency, because pure turbojets have a high specific thrust/high velocity exhaust, which is better suited to supersonic flight.

参考译文:改进的材料以及引入了双压缩机,例如布里斯托尔奥林匹斯[41]和普拉特和惠特尼JT3C发动机,提高了发动机的总压比,从而提高了热力学效率。然而,它们的推力效率较低,因为纯涡喷发动机具有高比冲/高速排气,更适合于超音速飞行。

The original low-bypass turbofan engines were designed to improve propulsive efficiency by reducing the exhaust velocity to a value closer to that of the aircraft. The Rolls-Royce Conway, the world’s first production turbofan, had a bypass ratio of 0.3, similar to the modern General Electric F404 fighter engine. Civilian turbofan engines of the 1960s, such as the Pratt & Whitney JT8D and the Rolls-Royce Spey, had bypass ratios closer to 1 and were similar to their military equivalents.

参考译文:最初的低涵道比涡扇发动机旨在通过将排气速度降低到接近飞机速度的值来提高推力效率罗尔斯-罗伊斯康威是世界上第一款量产涡扇发动机,其涵道比为0.3,类似于现代的通用电气F404战斗机发动机。20世纪60年代的民用涡扇发动机,如普惠JT8D和罗尔斯-罗伊斯Spey,涵道比更接近1,与其军用对应型号相似。

The first Soviet airliner powered by turbofan engines was the Tupolev Tu-124 introduced in 1962. It used the Soloviev D-20.[42] 164 aircraft were produced between 1960 and 1965 for Aeroflot and other Eastern Bloc airlines, with some operating until the early 1990s.

参考译文:首款由涡扇发动机驱动的苏联客机是1962年引入的图波列夫Tu-124。它使用的是Soloviev D-20发动机[42]。在1960年至1965年期间,共生产了164架飞机供俄罗斯航空和其他东方集团国家的航空公司使用,其中一些飞机一直运营到90年代初。

The first General Electric turbofan was the aft-fan CJ805-23, based on the CJ805-3 turbojet. It was followed by the aft-fan General Electric CF700 engine, with a 2.0 bypass ratio. This was derived from the General Electric J85/CJ610 turbojet 2,850 lbf (12,700 N) to power the larger Rockwell Sabreliner 75/80 model aircraft, as well as the Dassault Falcon 20, with about a 50% increase in thrust to 4,200 lbf (19,000 N). The CF700 was the first small turbofan to be certified by the Federal Aviation Administration (FAA). There were at one time over 400 CF700 aircraft in operation around the world, with an experience base of over 10 million service hours. The CF700 turbofan engine was also used to train Moon-bound astronauts in Project Apollo as the powerplant for the Lunar Landing Research Vehicle.

参考译文:第一款通用电气涡扇发动机是基于CJ805-3涡喷发动机的后置风扇CJ805-23。随后推出了后置风扇通用电气CF700发动机,涵道比为2.0。该发动机是由通用电气J85/CJ610涡喷发动机发展而来,具有2,850磅力(12,700牛顿)的推力,用于为更大的洛克韦尔Sabreliner 75/80型飞机和达索猎鹰20型飞机提供动力,并将推力增加了约50%至4,200磅力(19,000牛顿)。CF700是第一款获得美国联邦航空局(FAA)认证的小型涡扇发动机。曾经在全球范围内运营着400多架CF700飞机,累计使用时间超过1000万小时。CF700涡扇发动机还被用作阿波罗计划中前往月球的宇航员在登月研究车上的动力装置。

3. 常见类型 | Common types

3.1 小涵道比涡扇 | Low-bypass turbofan

A high-specific-thrust/low-bypass-ratio turbofan normally has a multi-stage fan behind inlet guide vanes, developing a relatively high pressure ratio and, thus, yielding a high (mixed or cold) exhaust velocity. The core airflow needs to be large enough to ensure there is sufficient core power to drive the fan. A smaller core flow/higher bypass ratio cycle can be achieved by raising the inlet temperature of the high-pressure (HP) turbine rotor.

参考译文:高比推力/低涵道比涡扇通常在进气导叶后面有多级风扇,形成相对较高的压力比,从而产生较高的(混合或冷)排气速度。核心气流需要足够大,以确保有足够的核心动力来驱动风扇。通过提高高压(HP)涡轮转子的进气温度,可以实现较小的核心流量/较高的涵道比循环。

To illustrate one aspect of how a turbofan differs from a turbojet, comparisons can be made at the same airflow (to keep a common intake for example) and the same net thrust (i.e. same specific thrust). A bypass flow can be added only if the turbine inlet temperature is not too high to compensate for the smaller core flow. Future improvements in turbine cooling/material technology can allow higher turbine inlet temperature, which is necessary because of increased cooling air temperature, resulting from an overall pressure ratio increase.

参考译文:为了说明涡扇与涡喷发动机的一方面区别,可以在相同的气流条件下进行比较(例如保持相同的进气口),并且具有相同的净推力(即相同的比推力)。只有在涡轮进口温度不太高以补偿较小的核心流量时,才能增加涵道流量。未来涡轮冷却/材料技术的改进可以实现更高的涡轮进口温度,这是必要的,因为整体压比增加导致冷却气温增加。

The resulting turbofan, with reasonable efficiencies and duct loss for the added components, would probably operate at a higher nozzle pressure ratio than the turbojet, but with a lower exhaust temperature to retain net thrust. Since the temperature rise across the whole engine (intake to nozzle) would be lower, the (dry power) fuel flow would also be reduced, resulting in a better specific fuel consumption (SFC).

参考译文:最终得到的涡扇发动机,通过合理的效率和管道损失来考虑新增组件,可能会以比涡喷发动机更高的喷嘴压力比运行,但出口温度较低以保持净推力。由于整个发动机(进气口到喷嘴)的温度升高较低,(干功)燃油流量也会减少,从而实现更好的比燃油消耗率(SFC)。

Some low-bypass ratio military turbofans (e.g. F404, JT8D) have variable inlet guide vanes to direct air onto the first fan rotor stage. This improves the fan surge margin (see compressor map).

参考译文:一些低涵道比的军用涡扇发动机(例如F404、JT8D)配备了可变进气导叶,用于将空气引导到第一级风扇叶片上。这可以改善风扇的涡流边缘(参见压气机特性曲线)。

3.2 加力涡轮风扇发动机 | Afterburning turbofan

Further information: Afterburner

更多信息:后燃烧室

Since the 1970s, most jet fighter engines have been low/medium bypass turbofans with a mixed exhaust, afterburner and variable area exit nozzle. An afterburner is a combustor located downstream of the turbine blades and directly upstream of the nozzle, which burns fuel from afterburner-specific fuel injectors. When lit, large volumes of fuel are burnt in the afterburner, raising the temperature of exhaust gases by a significant degree, resulting in a higher exhaust velocity/engine specific thrust. The variable geometry nozzle must open to a larger throat area to accommodate the extra volume and increased flow rate when the afterburner is lit. Afterburning is often designed to give a significant thrust boost for take off, transonic acceleration and combat maneuvers, but is very fuel intensive. Consequently, afterburning can be used only for short portions of a mission.

参考译文:自20世纪70年代以来,大多数喷气式战斗机发动机都采用低/中涵道比的涡扇发动机,配备了混合排气、加力燃烧室和可变面积喷嘴。加力燃烧室位于涡轮叶片的下游,直接位于喷嘴的上游,从加力燃烧室专用的燃油喷射器中燃烧燃料。当点火时,大量燃料在加力燃烧室中燃烧,显著提高排气气体的温度,从而使喷气速度/发动机比推力增加。可变几何喷嘴必须开到更大的喉部面积,以适应点火时的额外容积和增加的流量。加力燃烧通常设计用于起飞、超音速加速和战斗机动等阶段,能够显著提供推力增益,但燃油消耗量很大。因此,加力燃烧只能在任务的短时间内使用。

Unlike in the main engine, where stoichiometric temperatures in the combustor have to be reduced before they reach the turbine, an afterburner at maximum fuelling is designed to produce stoichiometric temperatures at entry to the nozzle, about 2,100 K (3,800 °R; 3,300 °F; 1,800 °C). At a fixed total applied fuel:air ratio, the total fuel flow for a given fan airflow will be the same, regardless of the dry specific thrust of the engine. However, a high specific thrust turbofan will, by definition, have a higher nozzle pressure ratio, resulting in a higher afterburning net thrust and, therefore, a lower afterburning specific fuel consumption (SFC). However, high specific thrust engines have a high dry SFC. The situation is reversed for a medium specific thrust afterburning turbofan: i.e., poor afterburning SFC/good dry SFC. The former engine is suitable for a combat aircraft which must remain in afterburning combat for a fairly long period, but has to fight only fairly close to the airfield (e.g. cross border skirmishes). The latter engine is better for an aircraft that has to fly some distance, or loiter for a long time, before going into combat. However, the pilot can afford to stay in afterburning only for a short period, before aircraft fuel reserves become dangerously low.

参考译文:与主发动机不同,燃烧室中的化学当量温度必须在进入涡轮之前降低,而最大燃油喷射量下的加力燃烧室被设计成在进入喷嘴时产生化学当量温度,约为2100K(3800°R;3300°F;1800°C)。在固定的燃油:空气比下,对于给定的风扇空气流量,总燃油流量将是相同的,而不考虑发动机的干功比推力。然而,高比推力的涡扇发动机将具有更高的喷嘴压力比,从而导致更高的加力燃烧净推力,因此加力燃烧的比燃油消耗率(SFC)较低。然而,高比推力发动机的干功比燃油消耗率较高。对于中等比推力的加力涡扇发动机来说情况就相反,即加力燃烧的比燃油消耗率较高,但干功比燃油消耗率较好。前一种发动机适用于需要在加力燃烧状态下进行相当长时间的战斗机,但只需在离机场相当近的地方战斗(例如,跨境冲突)。后一种发动机更适用于在进入战斗之前需要飞行一段距离或长时间盘旋的飞机。然而,飞行员只能在燃油储备变得危险低之前短时间内使用加力燃烧。

The first production afterburning turbofan engine was the Pratt & Whitney TF30, which initially powered the F-111 Aardvark and F-14 Tomcat. Current low-bypass military turbofans include the Pratt & Whitney F119, the Eurojet EJ200, the General Electric F110, the Klimov RD-33, and the Saturn AL-31, all of which feature a mixed exhaust, afterburner and variable area propelling nozzle.

参考译文:首款生产型加力涡扇发动机是普惠TF30,最初用于F-111 Aardvark和F-14 Tomcat战斗机。目前的低涵道比军用涡扇发动机包括普惠F119、欧洲合作EJ200、通用电气F110、克林姆夫RD-33和萨图尔AL-31,它们都采用混合排气、加力燃烧室和可变面积喷嘴。

3.3 大涵道比涡扇发动机 | High-bypass turbofan

Further information: Bypass ratio

更多信息:涵道比

To further improve fuel economy and reduce noise, almost all of today’s jet airliners and most military transport aircraft (e.g., the C-17) are powered by low-specific-thrust/high-bypass-ratio turbofans. These engines evolved from the high-specific-thrust/low-bypass-ratio turbofans used in such aircraft in the 1960s. Modern combat aircraft tend to use low-bypass ratio turbofans, and some military transport aircraft use turboprops.

参考译文:为了进一步提高燃油经济性和减少噪音,几乎所有现代喷气式客机和大多数军用运输机(例如C-17)都采用了低比推力/高涵道比涡扇发动机。这些发动机是从20世纪60年代使用在这些飞机上的高比推力/低涵道比涡扇发动机发展而来的。现代战斗机倾向于使用低涵道比涡扇发动机,一些军用运输机则采用涡桨发动机。

Low specific thrust is achieved by replacing the multi-stage fan with a single-stage unit. Unlike some military engines, modern civil turbofans lack stationary inlet guide vanes in front of the fan rotor. The fan is scaled to achieve the desired net thrust.

参考译文:通过使用单级风扇取代多级风扇,可以实现低比推力。与某些军用发动机不同,现代民用涡扇发动机在风扇转子前方缺乏静止进口导向叶片。风扇的尺寸调整以实现所需的净推力。

The core (or gas generator) of the engine must generate enough power to drive the fan at its rated mass flow and pressure ratio. Improvements in turbine cooling/material technology allow for a higher (HP) turbine rotor inlet temperature, which allows a smaller (and lighter) core, potentially improving the core thermal efficiency. Reducing the core mass flow tends to increase the load on the LP turbine, so this unit may require additional stages to reduce the average stage loading and to maintain LP turbine efficiency. Reducing core flow also increases bypass ratio. Bypass ratios greater than 5:1 are increasingly common; the Pratt & Whitney PW1000G, which entered commercial service in 2016, attains 12.5:1.

参考译文:发动机的核心部分(或气体发生器)必须产生足够的功率以驱动风扇达到额定质量流量和压力比。涡轮冷却/材料技术的改进使得高压(HP)涡轮转子进口温度可以更高,从而实现更小(和更轻)的核心,潜在提高核心热效率。减少核心质量流量往往会增加低压(LP)涡轮的负荷,因此可能需要额外的级数来减小平均级负荷并保持低压涡轮的效率。减少核心流量还会增加涵道比。超过5:1的涵道比越来越常见;普惠PW1000G发动机于2016年投入商业服务,其涵道比达到12.5:1。

Further improvements in core thermal efficiency can be achieved by raising the overall pressure ratio of the core. Improvements in blade aerodynamics can reduce the number of extra compressor stages required, and variable geometry (i.e., stators) enable high-pressure-ratio compressors to work surge-free at all throttle settings.

参考译文:通过提高核心的总压比,可以进一步提高核心的热效率。叶片空气动力学的改进可以减少所需的额外压缩机级数,而可变几何(即静子)使高压比压缩机能够在所有节流阀设置下无喘振地工作。

The first (experimental) high-bypass turbofan engine was the AVCO-Lycoming PLF1A-2, a Honeywell T55 turboshaft-derived engine that was first run in February 1962. The PLF1A-2 had a 40 in diameter (100 cm) geared fan stage, produced a static thrust of 4,320 lb (1,960 kg),[43] and had a bypass ratio of 6:1.[44] The General Electric TF39 became the first production model, designed to power the Lockheed C-5 Galaxy military transport aircraft.[22] The civil General Electric CF6 engine used a derived design. Other high-bypass turbofans are the Pratt & Whitney JT9D, the three-shaft Rolls-Royce RB211 and the CFM International CFM56; also the smaller TF34. More recent large high-bypass turbofans include the Pratt & Whitney PW4000, the three-shaft Rolls-Royce Trent, the General Electric GE90/GEnx and the GP7000, produced jointly by GE and P&W.

参考译文:第一台(实验性)高涵道比涡扇发动机是AVCO-Lycoming PLF1A-2,它是Honeywell T55涡轴发动机改进而来,于1962年2月首次运行。PLF1A-2采用直径40英寸(100厘米)的齿轮风扇级,静态推力为4,320磅(1,960公斤),涵道比为6:1。通用电气TF39成为第一款量产型号,专为推动洛克希德C-5银河军用运输机而设计。民用的通用电气CF6发动机采用了衍生设计。其他高涵道比涡扇发动机包括普惠JT9D,三轴式劳斯莱斯RB211和CFM国际CFM56,以及更小的TF34。更近期的大型高涵道比涡扇发动机包括普惠PW4000,三轴式劳斯莱斯特伦特,通用电气GE90/GEnx和GE与P&W联合生产的GP7000。

The lower the specific thrust of a turbofan, the lower the mean jet outlet velocity, which in turn translates into a high thrust lapse rate (i.e. decreasing thrust with increasing flight speed). See technical discussion below, item 2. Consequently, an engine sized to propel an aircraft at high subsonic flight speed (e.g., Mach 0.83) generates a relatively high thrust at low flight speed, thus enhancing runway performance. Low specific thrust engines tend to have a high bypass ratio, but this is also a function of the temperature of the turbine system.

参考译文:涡扇发动机的比推力越低,喷流出口速度越低,这反过来导致推力递减率高(即随着飞行速度增加推力减小)。请参见下面技术讨论,2项。因此,为了使飞机以高亚音速飞行(例如Mach 0.83),发动机需要产生相对较高的推力以在低速飞行时提升起飞距离性能。低比推力发动机往往具有高涵道比,但这也与涡轮系统的温度有关。

The turbofans on twin-engined transport aircraft produce enough take-off thrust to continue a take-off on one engine if the other engine shuts down after a critical point in the take-off run. From that point on the aircraft has less than half the thrust compared to two operating engines because the non-functioning engine is a source of drag. Modern twin engined airliners normally climb very steeply immediately after take-off. If one engine shuts down, the climb-out is much shallower, but sufficient to clear obstacles in the flightpath.

参考译文:双发运输机上的涡扇发动机产生足够的起飞推力,如果另一个发动机在起飞过程中的一个临界点后关闭,它可以继续在一个发动机上起飞。从那时起,飞机的推力还不到两个运行中的发动机的一半,因为不工作的发动机是阻力的来源。现代双引擎客机通常在起飞后立即急剧爬升。如果一个引擎关闭,爬升的幅度会小得多,但足以清除飞行路线上的障碍物。

The Soviet Union’s engine technology was less advanced than the West’s, and its first wide-body aircraft, the Ilyushin Il-86, was powered by low-bypass engines. The Yakovlev Yak-42, a medium-range, rear-engined aircraft seating up to 120 passengers, introduced in 1980, was the first Soviet aircraft to use high-bypass engines.

参考译文:苏联的发动机技术不如西方先进,它的第一架宽体飞机伊尔86 (Ilyushin Il-86)使用的是低涵道比发动机。雅科夫列夫雅克-42是一种可容纳120名乘客的中程后置发动机飞机,于1980年推出,是第一种使用高涵道比发动机的苏联飞机。

【代表性的大推力涡扇发动机 图集】

4. 涡轮风扇发动机配置 | Turbofan configurations

Turbofan engines come in a variety of engine configurations. For a given engine cycle (i.e., same airflow, bypass ratio, fan pressure ratio, overall pressure ratio and HP turbine rotor inlet temperature), the choice of turbofan configuration has little impact upon the design point performance (e.g., net thrust, SFC), as long as overall component performance is maintained. Off-design performance and stability is, however, affected by engine configuration.

参考译文:涡扇发动机有多种发动机配置。对于给定的发动机循环(即相同的气流、涵道比、风扇压力比、总压比和高压涡轮转子入口温度),只要保持整体部件性能,涡扇配置的选择对设计点性能(如净推力、SFC)的影响很小。然而,非设计性能和稳定性受到发动机配置的影响。

The basic element of a turbofan is a spool, a single combination of fan/compressor, turbine and shaft rotating at a single speed. For a given pressure ratio, the surge margin can be increased by two different design paths:

参考译文:涡轮风扇的基本部件是一个阀芯,它是风扇/压缩机、涡轮和以单一速度旋转的轴的单一组合。对于给定的压力比,可以通过两种不同的设计路径来增加喘振裕度:

- Splitting the compressor into two smaller spools rotating at different speeds, as with the Pratt & Whitney J57; or

参考译文:将压缩机分成两个较小的以不同速度旋转的线轴,如普惠J57;或 - Making the stator vane pitch adjustable, typically in the front stages, as with the J79.

参考译文:使定子叶片螺距可调,通常在前级,如J79。

Most modern western civil turbofans employ a relatively high-pressure-ratio high-pressure (HP) compressor, with many rows of variable stators to control surge margin at low rpm. In the three-spool RB211/Trent the core compression system is split into two, with the IP compressor, which supercharges the HP compressor, being on a different coaxial shaft and driven by a separate (IP) turbine. As the HP compressor has a modest pressure ratio its speed can be reduced surge-free, without employing variable geometry. However, because a shallow IP compressor working line is inevitable, the IPC has one stage of variable geometry on all variants except the −535, which has none.[45]

参考译文:大多数现代西方民用涡轮风扇采用相对高压力比的高压(HP)压缩机,配有多排可变定子来控制低转速时的喘振裕度。在三轴RB211/Trent中,核心压缩系统分为两个,其中IP压缩机增压HP压缩机,位于不同的同轴轴上,由单独的(IP)涡轮驱动。由于HP压缩机具有适度的压力比,它的速度可以在无浪涌的情况下降低,而无需采用可变几何形状。然而,由于浅IP压缩机工作线是不可避免的,IPC在所有变体上都有一个可变几何阶段,除了−535,它没有。[45]

4.1 单轴涡扇 | Single-shaft turbofan

Although far from common, the single-shaft turbofan is probably the simplest configuration, comprising a fan and high-pressure compressor driven by a single turbine unit, all on the same spool. The Snecma M53, which powers Dassault Mirage 2000 fighter aircraft, is an example of a single-shaft turbofan. Despite the simplicity of the turbomachinery configuration, the M53 requires a variable area mixer to facilitate part-throttle operation.

参考译文:虽然远不常见,但单轴涡扇可能是最简单的配置,包括一个风扇和高压压气机,由一个单一的涡轮单元驱动,都在同一个轴上。为达索幻影2000战斗机提供动力的斯奈克玛M53是单轴涡扇发动机的一个例子。尽管涡轮机械配置简单,M53需要一个可变区域混合器,以方便部分节流操作。

4.2 风扇在后的涡扇发动机 | Aft-fan turbofan

One of the earliest turbofans was a derivative of the General Electric J79 turbojet, known as the CJ805-23, which featured an integrated aft fan/low-pressure (LP) turbine unit located in the turbojet exhaust jetpipe. Hot gas from the turbojet turbine exhaust expanded through the LP turbine, the fan blades being a radial extension of the turbine blades. This arrangement introduces an additional gas leakage path compared to a front-fan configuration and was a problem with this engine with higher-pressure turbine gas leaking into the fan airflow.[46] An aft-fan configuration was later used for the General Electric GE36 UDF (propfan) demonstrator of the early 1980s.

参考译文:最早的涡扇发动机之一是通用电气J79涡喷发动机的衍生型,被称为CJ805-23,其特点是在涡喷发动机排气喷射管中安装了一个集成的尾部风扇/低压(LP)涡轮单元。热气体从涡轮喷射涡轮排气膨胀通过低压涡轮,风扇叶片是涡轮叶片的径向延伸。与前风扇配置相比,这种布置引入了一个额外的气体泄漏路径,这是高压涡轮气体泄漏到风扇气流中的发动机的一个问题。[46]后风扇配置后来用于1980年代早期通用电气GE36 UDF (profan)演示机。

In 1971 a concept was put forward by the NASA Lewis Research Center for a supersonic transport engine which operated as an aft-fan turbofan at take-off and subsonic speeds and a turbojet at higher speeds. This would give the low noise and high thrust characteristics of a turbofan at take-off, together with turbofan high propulsive efficiency at subsonic flight speeds. It would have the high propulsive efficiency of a turbojet at supersonic cruise speeds.[47]

参考译文:1971年,美国国家航空航天局刘易斯研究中心提出了一种超音速运输发动机的概念,这种发动机在起飞和亚音速时作为后扇涡扇发动机,在更高的速度下作为涡轮喷气发动机。这将使涡扇发动机在起飞时具有低噪音和高推力特性,同时在亚音速飞行速度下具有高推进效率。它将在超音速巡航速度下具有涡轮喷气发动机的高推进效率。[47]

4.3 基本的双转子 | Basic two-spool

Many turbofans have at least basic two-spool configuration where the fan is on a separate low pressure (LP) spool, running concentrically with the compressor or high pressure (HP) spool; the LP spool runs at a lower angular velocity, while the HP spool turns faster and its compressor further compresses part of the air for combustion.[citation needed] The BR710 is typical of this configuration. At the smaller thrust sizes, instead of all-axial blading, the HP compressor configuration may be axial-centrifugal (e.g., CFE CFE738), double-centrifugal or even diagonal/centrifugal (e.g. Pratt & Whitney Canada PW600).

参考译文:许多涡轮风扇至少有基本的双轴配置,风扇在一个单独的低压(LP)轴上,与压缩机或高压(HP)轴同心运行;低压阀芯以较低的角速度运行,而高压阀芯旋转得更快,其压缩机进一步压缩部分空气以供燃烧。BR710是典型的这种配置。在推力较小的情况下,高压压缩机的配置可以是轴向离心(例如CFE CFE738)、双离心甚至是对角/离心(例如普惠加拿大PW600),而不是全轴向叶片。

4.4 提高的双转子 | Boosted two-spool

Higher overall pressure ratios can be achieved by either raising the HP compressor pressure ratio or adding compressor (non-bypass) stages to the LP spool, between the fan and the HP compressor, to boost the latter. All of the large American turbofans (e.g. General Electric CF6, GE90, GE9X and GEnx plus Pratt & Whitney JT9D and PW4000) use booster stages. The Rolls-Royce BR715 is another example. The high bypass ratios used in modern civil turbofans tend to reduce the relative diameter of the booster stages, reducing their mean tip speed. Consequently, more booster stages are required to develop the necessary pressure rise.

参考译文:更高的总压力比可以通过提高高压压缩机压力比或在风机和高压压缩机之间的低压阀芯上增加压缩机(非旁路)级来实现,以提高后者。所有的大型美国涡轮风扇(例如通用电气的CF6, GE90, GE9X和GEnx加上普惠公司的JT9D和PW4000)都使用助推器级。劳斯莱斯BR715是另一个例子。现代民用涡扇采用的高涵道比往往会减小助推器级的相对直径,从而降低其平均叶尖速度。因此,需要更多的助推器级来产生必要的压力上升。

4.5 三转子 | Three-spool

Rolls-Royce chose a three-spool configuration for their large civil turbofans (i.e. the RB211 and Trent families), where the booster stages of a boosted two-spool configuration are separated into an intermediate pressure (IP) spool, driven by its own turbine. The first three-spool engine was the earlier Rolls-Royce RB.203 Trent of 1967.

参考译文:罗尔斯·罗伊斯为他们的大型民用涡轮风扇(即RB211和Trent系列)选择了三轴配置,其中增压的两轴配置的增压级被分离成一个中压(IP)轴,由自己的涡轮机驱动。第一个三轴发动机是1967年早期的劳斯莱斯RB.203 Trent。

The Garrett ATF3, powering the Dassault Falcon 20 business jet, has an unusual three spool layout with an aft spool not concentric with the two others.

参考译文:为达索猎鹰20公务机提供动力的加勒特ATF3发动机采用了不同寻常的三轴布局,其中一个后轴与另外两个轴不同轴。

Ivchenko Design Bureau chose the same configuration as Rolls-Royce for their Lotarev D-36 engine, followed by Lotarev/Progress D-18T and Progress D-436.

参考译文:伊夫琴科设计局为他们的Lotarev D-36发动机选择了与劳斯莱斯相同的配置,随后是Lotarev/Progress D-18T和Progress D-436。

The Turbo-Union RB199 military turbofan also has a three-spool configuration, as do the military Kuznetsov NK-25 and NK-321.

参考译文:Turbo-Union RB199军用涡扇发动机也采用三轴配置,与军用库兹涅佐夫NK-25和NK-321一样。

4.6 齿轮风扇 | Geared fan

Main article: Geared turbofan

主条目:齿轮传动涡轮风扇发动机

As bypass ratio increases, the fan blade tip speed increases relative to the LPT blade speed. This will reduce the LPT blade speed, requiring more turbine stages to extract enough energy to drive the fan. Introducing a (planetary) reduction gearbox, with a suitable gear ratio, between the LP shaft and the fan enables both the fan and LP turbine to operate at their optimum speeds. Examples of this configuration are the long-established Garrett TFE731, the Honeywell ALF 502/507, and the recent Pratt & Whitney PW1000G.

参考译文:当旁通比增加时,风扇叶尖速度相对于低压涡轮叶速度增加。这将减低压涡轮叶速度,需要更多的涡轮级来提取足够的能量来驱动风扇。通过在低压轴和风扇之间引入(行星式)减速器,具有合适的齿轮比,可以使风扇和低压涡轮以最佳速度运行。这种配置的例子有历史悠久的Garrett TFE731、Honeywell ALF 502/507,以及最近的Pratt & Whitney PW1000G。

4.7 军用涡扇发动机 | Military turbofans

Most of the configurations discussed above are used in civilian turbofans, while modern military turbofans (e.g., Snecma M88) are usually basic two-spool.

参考译文:上面讨论的大多数配置都用于民用涡轮风扇,而现代军用涡轮风扇(例如,斯奈克玛M88)通常是基本的两轴。

4.8 高压涡轮 | High-pressure turbine

Most civil turbofans use a high-efficiency, 2-stage HP turbine to drive the HP compressor. The CFM International CFM56 uses an alternative approach: a single-stage, high-work unit. While this approach is probably less efficient, there are savings on cooling air, weight and cost.

参考译文:大多数民用涡轮风扇发动机采用高效率的两级高压涡轮来驱动高压压气机。CFM国际CFM56采用了另一种方法:单级高功率单元。虽然这种方法可能效率较低,但在冷却空气、重量和成本方面节省了一些开销。

In the RB211 and Trent 3-spool engine series, the HP compressor pressure ratio is modest so only a single HP turbine stage is required. Modern military turbofans also tend to use a single HP turbine stage and a modest HP compressor.

参考译文:在RB211和Trent三轴发动机系列中,高压压气机压比较低,因此只需要一个高压涡轮级。现代军用涡扇发动机也倾向于使用单级高压涡轮级和较低压比的高压压气机。

4.9 低压涡轮 | Low-pressure turbine

Modern civil turbofans have multi-stage LP turbines (anywhere from 3 to 7). The number of stages required depends on the engine cycle bypass ratio and the boost (on boosted two-spools). A geared fan may reduce the number of required LPT stages in some applications.[48] Because of the much lower bypass ratios employed, military turbofans require only one or two LP turbine stages.

参考译文:现代民用涡轮风扇发动机通常具有多级低压涡轮(从3级到7级不等)。所需级数取决于发动机循环的副推力比和增压(对于增压的双轴发动机)。在某些应用中,使用齿轮风扇可能会减少所需的低压涡轮级数。由于采用的副推力比较低,军用涡扇发动机只需要1~2级低压涡轮。

5. 整体性能 Overall performance

5.1 循环改进 | Cycle improvements

Consider a mixed turbofan with a fixed bypass ratio and airflow. Increasing the overall pressure ratio of the compression system raises the combustor entry temperature. Therefore, at a fixed fuel flow there is an increase in (HP) turbine rotor inlet temperature. Although the higher temperature rise across the compression system implies a larger temperature drop over the turbine system, the mixed nozzle temperature is unaffected, because the same amount of heat is being added to the system. There is, however, a rise in nozzle pressure, because overall pressure ratio increases faster than the turbine expansion ratio, causing an increase in the hot mixer entry pressure. Consequently, net thrust increases, whilst specific fuel consumption (fuel flow/net thrust) decreases. A similar trend occurs with unmixed turbofans.

参考译文:考虑一个具有固定副推力比和空气流量的混合涡扇发动机。增加压缩系统的总压比会提高燃烧室进口温度。因此,在固定燃料流量的情况下,(HP)涡轮转子进口温度会增加。尽管压缩系统温度升高意味着涡轮系统温度降低更大,但混合喷管温度不受影响,因为系统中添加的热量相同。然而,喷嘴压力上升,因为整体压力比增加得比涡轮膨胀比快,导致热混合器进口压力增加。因此,净推力增加,而比油耗(燃料流量/净推力)减少。非混合涡扇发动机也有类似的趋势。

Turbofan engines can be made more fuel efficient by raising overall pressure ratio and turbine rotor inlet temperature in unison. However, better turbine materials or improved vane/blade cooling are required to cope with increases in both turbine rotor inlet temperature and compressor delivery temperature. Increasing the latter may require better compressor materials.

参考译文:通过同时提高总压比和涡轮转子进口温度,涡扇发动机可以实现更高的燃油效率。然而,为了应对涡轮转子进口温度和压缩机出口温度的增加,需要更好的涡轮材料或改进的导叶/叶片冷却技术。增加后者可能需要更好的压缩机材料。

The overall pressure ratio can be increased by improving fan (or) LP compressor pressure ratio or HP compressor pressure ratio. If the latter is held constant, the increase in (HP) compressor delivery temperature (from raising overall pressure ratio) implies an increase in HP mechanical speed. However, stressing considerations might limit this parameter, implying, despite an increase in overall pressure ratio, a reduction in HP compressor pressure ratio.

参考译文:总压比可以通过改善风扇或低压压缩机压力比或高压压缩机压力比来提高。如果将高压压缩机压力比保持不变,则由于提高总压比而导致的(HP)压缩机出口温度增加意味着(HP)机械速度增加。然而,应考虑到应力的限制可能限制此参数,这意味着尽管总压比增加,但高压压缩机压力比减小。

According to simple theory, if the ratio of turbine rotor inlet temperature/(HP) compressor delivery temperature is maintained, the HP turbine throat area can be retained. However, this assumes that cycle improvements are obtained, while retaining the datum (HP) compressor exit flow function (non-dimensional flow). In practice, changes to the non-dimensional speed of the (HP) compressor and cooling bleed extraction would probably make this assumption invalid, making some adjustment to HP turbine throat area unavoidable. This means the HP turbine nozzle guide vanes would have to be different from the original. In all probability, the downstream LP turbine nozzle guide vanes would have to be changed anyway.

参考译文:根据简单理论,如果保持涡轮转子进口温度与(HP)压缩机出口温度的比值不变,则可以保持(HP)涡轮喉部的面积。然而,这假设在保持数据(HP)压缩机出口流函数(无量纲流量)的同时,可以获得循环改进。实际上,(HP)压缩机的无量纲速度和冷却抽取可能会使得这个假设无效,从而不可避免地对(HP)涡轮喉部面积进行一些调整。这意味着(HP)涡轮导叶必须与最初的设计不同。很可能,下游的低压涡轮导叶也必须进行改变。

5.2 推力增长 | Thrust growth

Thrust growth is obtained by increasing core power. There are two basic routes available:

参考译文:推力增长是通过增加核心功率来实现的。有两条基本路线可供选择:

- hot route: increase HP turbine rotor inlet temperature

参考译文:热路线:提高高压涡轮转子入口温度 - cold route: increase core mass flow

参考译文:冷路线:增加堆芯质量流量

Both routes require an increase in the combustor fuel flow and, therefore, the heat energy added to the core stream.

参考译文:这两种途径都需要增加燃烧室的燃料流量,因此,热量增加到核心流。

The hot route may require changes in turbine blade/vane materials or better blade/vane cooling. The cold route can be obtained by one of the following:

参考译文:热路线可能需要改变涡轮叶片/叶片材料或更好的叶片/叶片冷却。冷路由可以通过以下方式获取:

- adding booster stages to the LP/IP compression

参考译文:将助推器级添加到LP/IP压缩中 - adding a zero-stage to the HP compression

参考译文:为HP压缩添加零级 - improving the compression process, without adding stages (e.g. higher fan hub pressure ratio)

参考译文:改进压缩过程,无需增加级(如提高风机轮毂压力比)

all of which increase both overall pressure ratio and core airflow.

参考译文:所有这些都增加了总压比和核心气流。

Alternatively, the core size can be increased, to raise core airflow, without changing overall pressure ratio. This route is expensive, since a new (upflowed) turbine system (and possibly a larger IP compressor) is also required.

参考译文:或,可以增加核心尺寸,以提高核心气流,而不改变总压比。这条路径是昂贵的,因为还需要一个新的(上升式)涡轮系统(可能还需要一个更大的中压压缩机)。

Changes must also be made to the fan to absorb the extra core power. On a civil engine, jet noise considerations mean that any significant increase in take-off thrust must be accompanied by a corresponding increase in fan mass flow (to maintain a T/O specific thrust of about 30 lbf/lb/s).

参考译文:还必须对风扇进行改变,以吸收额外的核心功率。在民用发动机上,射流噪声考虑因素意味着任何显著增加的起飞推力都必须伴随着风扇质量流量的相应增加(以保持约为30磅/磅/秒的起飞比推力)。

5.3 技术讨论 | Technical discussion

1. Specific thrust (net thrust/intake airflow) is an important parameter for turbofans and jet engines in general. Imagine a fan (driven by an appropriately sized electric motor) operating within a pipe, which is connected to a propelling nozzle. It is fairly obvious, the higher the fan pressure ratio (fan discharge pressure/fan inlet pressure), the higher the jet velocity and the corresponding specific thrust. Now imagine we replace this set-up with an equivalent turbofan – same airflow and same fan pressure ratio. Obviously, the core of the turbofan must produce sufficient power to drive the fan via the low-pressure (LP) turbine. If we choose a low (HP) turbine inlet temperature for the gas generator, the core airflow needs to be relatively high to compensate. The corresponding bypass ratio is therefore relatively low. If we raise the turbine inlet temperature, the core airflow can be smaller, thus increasing bypass ratio. Raising turbine inlet temperature tends to increase thermal efficiency and, therefore, improve fuel efficiency.

参考译文:对于涡扇发动机和喷气发动机来说,比推力(净推力/进气气流)是一个重要的参数。想象一个由适当尺寸的电动机驱动的风扇,在与一个推进喷嘴连接的管道内运行。很明显,风扇压比(风扇排气压力/风扇进气压力)越高,喷气速度越高,相应的比推力也越高。现在想象我们用一个等效的涡扇代替这个设备——相同的气流和相同的风扇压比。显然,涡扇的核心必须通过低压(LP)涡轮产生足够的功率来驱动风扇。如果我们选择一个较低的(HP)涡轮进口温度作为气体发生器,核心气流需要相对较高来进行补偿。因此,相应的旁路比相对较低。如果我们提高涡轮进口温度,核心气流可以更小,从而增加旁路比。提高涡轮进口温度往往会增加热效率,因此提高燃油效。

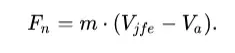

2. Naturally, as altitude increases, there is a decrease in air density and, therefore, the net thrust of an engine. There is also a flight speed effect, termed thrust lapse rate. Consider the approximate equation for net thrust again:

参考译文:当海拔增加时,空气密度减小,因此发动机的净推力也会减小。还有一种飞行速度效应,被称为推力衰减率。再考虑净推力的近似方程:

With a high specific thrust (e.g., fighter) engine, the jet velocity is relatively high, so intuitively one can see that increases in flight velocity have less of an impact upon net thrust than a medium specific thrust (e.g., trainer) engine, where the jet velocity is lower. The impact of thrust lapse rate upon a low specific thrust (e.g., civil) engine is even more severe. At high flight speeds, high-specific-thrust engines can pick up net thrust through the ram rise in the intake, but this effect tends to diminish at supersonic speeds because of shock wave losses.

参考译文:对于高比推力(例如战斗机)发动机,喷气速度相对较高,因此直观上可以看出,飞行速度的增加对净推力的影响较小,而对于中等比推力(例如教练机)发动机来说,喷气速度较低,对净推力的影响较大。对于低比推力(例如民用)发动机来说,推力衰减率的影响更加严重。在高速飞行时,高比推力发动机可以通过进气道的气流上升来增加净推力,但在超音速速度下,由于激波损失,这种效应会减弱。

3. Thrust growth on civil turbofans is usually obtained by increasing fan airflow, thus preventing the jet noise becoming too high. However, the larger fan airflow requires more power from the core. This can be achieved by raising the overall pressure ratio (combustor inlet pressure/intake delivery pressure) to induce more airflow into the core and by increasing turbine inlet temperature. Together, these parameters tend to increase core thermal efficiency and improve fuel efficiency.

参考译文:民用涡扇发动机通常通过增加风扇气流来实现推力增长,从而防止喷气噪声过高。然而,更大的风扇气流需要更多核心部分的动力。这可以通过提高总压比(燃烧器进口压力/进气道进口压力)来实现,以促使更多气流进入核心,并增加涡轮进口温度。这些参数共同增加了核心热效率,并提高了燃油效率。

4. Some high-bypass-ratio civil turbofans use an extremely low area ratio (less than 1.01), convergent-divergent, nozzle on the bypass (or mixed exhaust) stream, to control the fan working line. The nozzle acts as if it has variable geometry. At low flight speeds the nozzle is unchoked (less than a Mach number of unity), so the exhaust gas speeds up as it approaches the throat and then slows down slightly as it reaches the divergent section. Consequently, the nozzle exit area controls the fan match and, being larger than the throat, pulls the fan working line slightly away from surge. At higher flight speeds, the ram rise in the intake increases nozzle pressure ratio to the point where the throat becomes choked (M=1.0). Under these circumstances, the throat area dictates the fan match and, being smaller than the exit, pushes the fan working line slightly towards surge. This is not a problem, since fan surge margin is much better at high flight speeds.

参考译文:一些高涵道比的民用涡扇发动机在旁通(或混合排气)流上使用了一个极低的面积比(小于1.01)的收敛-扩张喷嘴,以控制风扇的工作线。这个喷嘴的作用就像是具有可变几何形状一样。在低飞行速度下,喷嘴处于非窒息状态(马赫数小于1),因此排气气体在接近喉部时加速,然后在达到扩张段时略微减速。因此,喷嘴出口面积控制了风扇的匹配,由于比喉部大,使得风扇工作线略微远离激涡。在更高的飞行速度下,进气道的气流上升增加了喷嘴的压力比,使得喉部被窒息(M=1.0)。在这种情况下,喉部面积决定了风扇的匹配,由于比出口小,使得风扇工作线略微靠近激涡。这并不是一个问题,因为在高飞行速度下,风扇的激涡余量要好得多。

5. The off-design behaviour of turbofans is illustrated under compressor map and turbine map.

参考译文:在压气机图和涡轮图两种情况下阐述了涡扇的非设计特性。

6. Because modern civil turbofans operate at low specific thrust, they require only a single fan stage to develop the required fan pressure ratio. The desired overall pressure ratio for the engine cycle is usually achieved by multiple axial stages on the core compression. Rolls-Royce tend to split the core compression into two with an intermediate pressure (IP) supercharging the HP compressor, both units being driven by turbines with a single stage, mounted on separate shafts. Consequently, the HP compressor need develop only a modest pressure ratio (e.g., ~4.5:1). US civil engines use much higher HP compressor pressure ratios (e.g., ~23:1 on the General Electric GE90) and tend to be driven by a two-stage HP turbine. Even so, there are usually a few IP axial stages mounted on the LP shaft, behind the fan, to further supercharge the core compression system. Civil engines have multi-stage LP turbines, the number of stages being determined by the bypass ratio, the amount of IP compression on the LP shaft and the LP turbine blade speed.

参考译文:由于现代民用涡扇发动机的比推力较低,所以只需要一个风扇级来达到所需的风扇压力比。通常,发动机循环的期望总压比是通过核心压缩中的多个轴向级来实现的。劳斯莱斯公司倾向于将核心压缩分成两部分,中间压力(IP)增压高压(HP)压缩机,这两个部件由单级涡轮驱动,安装在单独的轴上。因此,HP压缩机只需达到适度的压力比(例如,约为4.5:1)。美国的民用发动机使用更高的HP压缩机压力比(例如,通用电气GE90的压力比约为23:1),并且倾向于由两级HP涡轮驱动。即便如此,在风扇后面的LP轴上通常仍然有一些IP轴向级,进一步增压核心压缩系统。民用发动机具有多级LP涡轮,级数由旁通比、LP轴上的IP压缩量和LP涡轮叶片速度来确定。

7. Because military engines usually have to be able to fly very fast at sea level, the limit on HP compressor delivery temperature is reached at a fairly modest design overall pressure ratio, compared with that of a civil engine. Also the fan pressure ratio is relatively high, to achieve a medium to high specific thrust. Consequently, modern military turbofans usually have only 5 or 6 HP compressor stages and require only a single-stage HP turbine. Low-bypass-ratio military turbofans usually have one LP turbine stage, but higher bypass ratio engines need two stages. In theory, by adding IP compressor stages, a modern military turbofan HP compressor could be used in a civil turbofan derivative, but the core would tend to be too small for high thrust applications.

参考译文:由于军用发动机通常需要在海平面上以非常高的速度飞行,与民用发动机相比,HP压缩机传递温度的限制在相对较低的设计总压比下就会达到。此外,为了实现中到高的比推力,风扇压比相对较高。因此,现代军用涡扇发动机通常只有5或6个HP压缩机级别,只需要单级HP涡轮。低旁通比的军用涡扇发动机通常只有一个LP涡轮级别,而高旁通比的发动机则需要两个级别。理论上,通过增加IP压缩机级数,现代军用涡扇发动机的HP压缩机可以用于民用涡扇的衍生型号,但核心往往对于高推力应用来说太小。

6. 提升 | Improvements

6.1 空气动力学模型 | Aerodynamic modelling

Aerodynamics is a mix of subsonic, transonic and supersonic airflow on a single fan/gas compressor blade in a modern turbofan. The airflow past the blades has to be maintained within close angular limits to keep the air flowing against an increasing pressure. Otherwise the air will come back out of the intake.[49]

参考译文:现代涡扇发动机的气动特性是亚音速、跨音速和超音速气流在单个风扇/气体压缩机叶片上的混合。为了保持气流顺着逐渐增加的压力流动,必须在接近的角度限制下维持气流通过叶片。否则,气流将会从进气口逆流出来。

The Full Authority Digital Engine Control (FADEC) needs accurate data for controlling the engine. The critical turbine inlet temperature (TIT) is too harsh an environment, at 1,700 °C (3,100 °F) and 17 bar (250 psi), for reliable sensors. Therefore, during development of a new engine type a relation is established between a more easily measured temperature like exhaust gas temperature and the TIT. Monitoring the exhaust gas temperature is then used to make sure the engine does not run too hot.[49]

参考译文:全权数字式发动机控制系统(FADEC)需要准确的数据来控制发动机。关键的涡轮进口温度(TIT)对于可靠传感器来说是一个过于恶劣的环境,温度高达1,700°C(3,100°F),压力达到17巴(250磅/平方英寸)。因此,在开发新型发动机时,需要建立排气温度等更容易测量的温度与TIT之间的关系。监测排气温度然后用于确保发动机不会过热运行。

6.2 叶片技术 | Blade technology

A 100 g (3.5 oz) turbine blade is subjected to 1,700 °C (3,100 °F), at 17 bar (250 psi) and a centrifugal force of 40 kN (9,000 lbf), well above the point of plastic deformation and even above the melting point. Exotic alloys, sophisticated air cooling schemes and special mechanical design are needed to keep the physical stresses within the strength of the material. Rotating seals must withstand harsh conditions for 10 years, 20,000 missions and rotating at 10 to 20,000 rpm.[49]

参考译文:一个100克(3.5盎司)的涡轮叶片承受着1,700°C(3,100°F)的高温,17巴(250磅/平方英寸)的高压和40千牛(9,000磅力)的离心力,远超过塑性变形点甚至超过熔点。需要使用特殊的合金、复杂的空气冷却方案和特殊的机械设计来使物理应力保持在材料的强度范围内。旋转密封件必须能够在艰苦环境下工作10年,完成20,000次任务,并以10至20,000转/分钟的速度旋转。

6.3 风扇叶片 | Fan blades

Fan blades have been growing as jet engines have been getting bigger: each fan blade carries the equivalent of nine double-decker buses and swallows air the equivalent volume of a squash court every second. Advances in computational fluid dynamics (CFD) modelling have permitted complex, 3D curved shapes with very wide chord, keeping the fan capabilities while minimizing the blade count to lower costs. Coincidentally, the bypass ratio grew to achieve higher propulsive efficiency and the fan diameter increased.[50]

参考译文:随着喷气发动机的尺寸越来越大,风扇叶片也在不断增长:每个风扇叶片相当于九辆双层巴士的负载,并且每秒吸入相当于一个壁球场的空气体积。计算流体力学(CFD)建模的进步使得可以设计复杂的、三维曲面的叶片,具有非常宽的弦长,既可以保持风扇的性能,又能尽量减少叶片数量以降低成本。巧合的是,旁通比增加以提高推进效率,风扇直径也增加了。

Rolls-Royce pioneered the hollow, titanium wide-chord fan blade in the 1980s for aerodynamic efficiency and foreign object damage resistance in the RB211 then for the Trent. GE Aviation introduced carbon fiber composite fan blades on the GE90 in 1995, manufactured today with a carbon-fiber tape-layer process. GE partner Safran developed a 3D woven technology with Albany Composites for the CFM56 and CFM LEAP engines.[50]

参考译文:罗尔斯·罗伊斯(Rolls-Royce)在上世纪80年代为了提高空气动力效率和抵抗异物损伤,在RB211发动机上首创了空心的钛合金宽弦风扇叶片,之后又在特伦特(Trent)发动机上采用了这一技术。GE航空公司于1995年在GE90发动机上引入了碳纤维复合材料风扇叶片,目前使用碳纤维带层工艺进行制造。GE的合作伙伴赛峰公司(Safran)与Albany Composites共同开发了一种用于CFM56和CFM LEAP发动机的三维编织技术。

6.4 未来的进步 | Future progress

Engine cores are shrinking as they are operating at higher pressure ratios and becoming more efficient, and become smaller compared to the fan as bypass ratios increase. Blade tip clearances are harder to maintain at the exit of the high-pressure compressor where blades are 0.5 in (13 mm) high or less; backbone bending further affects clearance control as the core is proportionately longer and thinner and the fan to low-pressure turbine driveshaft is in constrained space within the core.[51]

参考译文:随着发动机的工作压力比增加和效率提高,发动机核心正在缩小,并且与风扇相比,核心在旁通比增加时变得更小。在高压压缩机出口处,叶片尖端间隙的维护更加困难,因为叶片的高度只有0.5英寸(13毫米)或更低;骨架的弯曲进一步影响了间隙控制,因为核心部分相对较长而薄,而风扇与低压涡轮驱动轴则位于核心内的受限空间内。

For Pratt & Whitney VP technology and environment Alan Epstein “Over the history of commercial aviation, we have gone from 20% to 40% [cruise efficiency], and there is a consensus among the engine community that we can probably get to 60%”.[52]

参考译文:普惠公司技术与环境副总裁艾伦·爱泼斯坦表示:“在商业航空历史上,我们的巡航效率从20%提高到了40%,发动机界普遍认为我们可能可以达到60%的效率。”

Geared turbofans and further fan pressure ratio reductions will continue to improve propulsive efficiency. The second phase of the FAA’s Continuous Lower Energy, Emissions and Noise (CLEEN) program is targeting for the late 2020s reductions of 33% fuel burn, 60% emissions and 32 dB EPNdb noise compared with the 2000s state-of-the-art.[53] In summer 2017 at NASA Glenn Research Center in Cleveland, Ohio, Pratt has finished testing a very-low-pressure-ratio fan on a PW1000G, resembling an open rotor with fewer blades than the PW1000G’s 20.[52]

参考译文:通过齿轮涡轮风扇和进一步降低风扇压力比,推进效率将继续得到提高。美国联邦航空管理局FAA)“持续低能、低排放和低噪音”(CLEEN)计划的第二阶段旨在在2020年代后期相比于2000年代的先进技术水平,实现燃油燃烧降低33%、排放降低60%和噪音降低32 dB EPNdb的目标。2017年夏季,在俄亥俄州克利夫兰的NASA格伦研究中心,普惠公司已经完成了对PW1000G发动机上的一个非常低压比风扇的测试,该风扇类似于具有较少叶片的开放式转子,少于PW1000G的20片叶片。

The weight and size of the nacelle would be reduced by a short duct inlet, imposing higher aerodynamic turning loads on the blades and leaving less space for soundproofing, but a lower-pressure-ratio fan is slower. UTC Aerospace Systems Aerostructures will have a full-scale ground test in 2019 of its low-drag Integrated Propulsion System with a thrust reverser, improving fuel burn by 1% and with 2.5-3 EPNdB lower noise.[52]

参考译文:通过使用较短的进气道,发动机外壳的重量和尺寸可以减小,但这会给叶片施加更高的空气动力学转向负载,并且留下较少的空间用于隔音。然而,低压比风扇的转速较慢。UTC航空航天系统公司的航空结构部门将在2019年进行其低阻力综合推进系统的全尺寸地面测试,该系统配备了一个推力反向器,燃油消耗降低了1%,噪音降低了2.5-3 EPNdB。

Safran can probably deliver another 10–15% in fuel efficiency through the mid-2020s before reaching an asymptote, and next will have to introduce a breakthrough: to increase the bypass ratio to 35:1 instead of 11:1 for the CFM LEAP, it is demonstrating a counterrotating open rotor unducted fan (propfan) in Istres, France, under the European Clean Sky technology program. Modeling advances and high specific strength materials may help it succeed where previous attempts failed. When noise levels will be within current standards and similar to the Leap engine, 15% lower fuel burn will be available and for that Safran is testing its controls, vibration and operation, while airframe integration is still challenging.[52]

参考译文:到2020年代中期,萨弗兰公司可能可以通过引入一项突破性技术,将燃油效率再提高10-15%。他们计划将副推力比提高到35:1,而不是CFM LEAP发动机的11:1。他们正在法国伊斯特尔进行一个反向旋转的开放式转子无罩风扇(propfan)的展示,该项目是欧洲Clean Sky技术计划的一部分。通过模拟进展和高特殊强度材料,他们可能能够在以前的尝试中失败的地方取得成功。当噪音水平符合当前标准并与Leap发动机相似时,将可实现15%的燃油燃烧降低。为此,萨弗兰公司正在测试其控制、振动和操作,但机身整合仍然具有挑战性。

For GE Aviation, the energy density of jet fuel still maximises the Breguet range equation and higher pressure ratio cores; lower pressure ratio fans, low-loss inlets and lighter structures can further improve thermal, transfer and propulsive efficiency. Under the U.S. Air Force’s Adaptive Engine Transition Program, adaptive thermodynamic cycles will be used for the sixth-generation jet fighter, based on a modified Brayton cycle and Constant volume combustion. Additive manufacturing in the advanced turboprop will reduce weight by 5% and fuel burn by 20%.[52]

参考译文:对于GE航空公司来说,喷气燃料的能量密度仍然最大化了布雷盖茨航程方程和更高压力比的核;较低压力比的风扇、低损耗的进气道和更轻的结构可以进一步提高热能、传热和推力效率。在美国空军的自适应发动机过渡计划下,自适应热力循环将用于第六代喷气式战斗机,基于改进的布雷顿循环和恒容燃烧。先进涡轮螺旋桨发动机中的增材制造将减轻重量5%并降低燃油燃烧20%。

Rotating and static ceramic matrix composite (CMC) parts operates 500 °F (260 °C) hotter than metal and are one-third its weight. With $21.9 million from the Air Force Research Laboratory, GE is investing $200 million in a CMC facility in Huntsville, Alabama, in addition to its Asheville, North Carolina site, mass-producing silicon carbide matrix with silicon-carbide fibers in 2018. CMCs will be used ten times more by the mid-2020s: the CFM LEAP requires 18 CMC turbine shrouds per engine and the GE9X will use it in the combustor and for 42 HP turbine nozzles.[52]

参考译文:旋转和静止的陶瓷基复合材料(CMC)零部件的运行温度比金属高500°F(260°C),重量只有其三分之一。GE正在从空军研究实验室获得2190万美元的资金,在亚拉巴马州亨茨维尔建立一座CMC设施,此外还有位于北卡罗来纳州阿什维尔的工厂。2018年,GE将开始大规模生产硅碳化物基体和碳化硅纤维的CMC。到2020年代中期,CMC的使用量将增加十倍:CFM LEAP发动机每个需要18个CMC涡轮罩,而GE9X发动机将在燃烧室和42个高压涡轮喷嘴中使用CMC材料。

Rolls-Royce Plc aim for a 60:1 pressure ratio core for the 2020s Ultrafan and began ground tests of its 100,000 hp (75,000 kW) gear for 100,000 lbf (440 kN) and 15:1 bypass ratios. Nearly stoichiometric turbine entry temperatures approaches the theoretical limit and its impact on emissions has to be balanced with environmental performance goals. Open rotors, lower pressure ratio fans and potentially distributed propulsion offer more room for better propulsive efficiency. Exotic cycles, heat exchangers and pressure gain/constant volume combustion can improve thermodynamic efficiency. Additive manufacturing could be an enabler for intercooler and recuperators. Closer airframe integration and hybrid or electric aircraft can be combined with gas turbines.[52]

参考译文:劳斯莱斯公司的目标是在2020年代的Ultrafan发动机中实现60:1的压力比核心,并已开始对其10万马力(75,000千瓦)的齿轮进行100,000磅(440千牛顿)和15:1的副推力比的地面测试。接近化学计量的涡轮进口温度接近理论极限,其对排放的影响必须与环境性能目标相平衡。开放式转子、较低压力比的风扇和潜在的分布式推进技术提供了更多改善推力效率的空间。异类循环、热交换器和增压/恒容燃烧可以提高热力学效率。增材制造技术可以为中冷器和回收器提供可能。更紧密的机身整合和混合动力或电动飞机可以与燃气涡轮相结合。

Current Rolls-Royce engines have a 72–82% propulsive efficiency and 42–49% thermal efficiency for a 0.63–0.49 lb/lbf/h (64,000–50,000 g/kN/h) TSFC at Mach 0.8, and aim for theoretical limits of 95% for open rotor propulsive efficiency and 60% for thermal efficiency with stoichiometric turbine entry temperature and 80:1 overall pressure ratio for a 0.35 lb/lbf/h (36,000 g/kN/h) TSFC[54]

参考译文:目前劳斯莱斯的发动机在Mach 0.8下具有72-82%的推力效率和42-49%的热效率,燃油消耗率为0.63-0.49磅/千磅推力/小时(64,000-50,000克/千牛顿/小时)。劳斯莱斯的目标是在具有化学计量涡轮进口温度和80:1总压力比的情况下,实现开放转子的推力效率达到95%,热效率达到60%,燃油消耗率为0.35磅/千磅推力/小时(36,000克/千牛顿/小时)。

As teething troubles may not show up until several thousand hours, the latest turbofans technical problems disrupt airlines operations and manufacturers deliveries while production rates are rising sharply. Trent 1000 cracked blades grounded almost 50 Boeing 787s and reduced ETOPS to 2.3 hours down from 5.5, costing Rolls-Royce plc almost $950 million. PW1000G knife-edge seal fractures have caused Pratt & Whitney to fall way behind in deliveries, leaving about 100 engineless A320neos waiting for their powerplants. The CFM LEAP introduction was smoother but a ceramic composite HP Turbine coating is prematurely lost, necessitating a new design, causing 60 A320neo engine removal for modification, as deliveries are up to six weeks late.[55]

参考译文:由于一些技术问题可能要到数千小时后才会显现,最新的涡扇发动机的技术问题扰乱了航空公司的运营和制造商的交付,而生产率却在急剧上升。特伦特1000发动机的叶片开裂导致近50架波音787停飞,并将ETOPS从5.5小时降低到2.3小时,给劳斯莱斯公司造成了近9.5亿美元的损失。PW1000G发动机的刀口密封裂纹导致普惠公司的交付大大延迟,约有100架没有发动机的A320neo等待着安装动力装置。CFM LEAP的推出相对顺利,但陶瓷复合材料高压涡轮涂层过早失效,需要进行新的设计,导致60架A320neo发动机需要进行修改,交付时间延迟了最多六周。

On a widebody, Safran estimates 5–10% of fuel could be saved by reducing power intake for hydraulic systems, while swapping to electrical power could save 30% of weight, as initiated on the Boeing 787, while Rolls-Royce plc hopes for up to 5%.[56]

参考译文:Safran估计,在宽体飞机上,通过减少液压系统的动力输入,可以节省5-10%的燃油,而转向使用电力可以节省30%的重量,正如波音787所采取的措施,而劳斯莱斯公司则希望能够达到5%的节省。

7. 制造商 | Manufacturers

Main article: List of turbofan manufacturers

主条目:涡轮风扇发动机制造商列表

The turbofan engine market is dominated by General Electric, Rolls-Royce plc and Pratt & Whitney, in order of market share. General Electric and Safran of France have a joint venture, CFM International. Pratt & Whitney also have a joint venture, International Aero Engines with Japanese Aero Engine Corporation and MTU Aero Engines of Germany, specializing in engines for the Airbus A320 family. Pratt & Whitney and General Electric have a joint venture, Engine Alliance selling a range of engines for aircraft such as the Airbus A380.

参考译文:涡扇发动机市场的主导地位由通用电气、劳斯莱斯公司和普惠公司依据市场份额排名确定。通用电气与法国赛峰有一个合资企业,即CFM国际公司。普惠公司也与日本航空发动机公司和德国MTU航空发动机有一个合资企业,专门生产空客A320系列飞机的发动机。普惠公司和通用电气还有一个合资企业,即发动机联盟(Engine Alliance),销售一系列适用于空客A380等飞机的发动机。

For airliners and cargo aircraft, the in-service fleet in 2016 is 60,000 engines and should grow to 103,000 in 2035 with 86,500 deliveries according to Flight Global. A majority will be medium-thrust engines for narrow-body aircraft with 54,000 deliveries, for a fleet growing from 28,500 to 61,000. High-thrust engines for wide-body aircraft, worth 40–45% of the market by value, will grow from 12,700 engines to over 21,000 with 18,500 deliveries. The regional jet engines below 20,000 lb (89 kN) fleet will grow from 7,500 to 9,000 and the fleet of turboprops for airliners will increase from 9,400 to 10,200. The manufacturers market share should be led by CFM with 44% followed by Pratt & Whitney with 29% and then Rolls-Royce and General Electric with 10% each.[57]

参考译文:根据Flight Global的数据,2016年民航客机和货运飞机的在役发动机数量为60,000台,预计到2035年将增至103,000台,交付为86,500台大部分发动机将用于窄体飞机,交付数量为54,000台,使得该类飞机的在役发动机数量从28,500台增至61,000台。用于宽体飞机的大推力发动机(价值占市场总值的40-45%)将从12,700台增至21,000台,交付数量为18,500台。20,000磅(89 kN)以下的地区客机发动机数量将从7,500台增至9,000台,而供民航飞机使用的涡桨发动机的数量将从9,400台增至10,200台。制造商的市场份额将由CFM领先,占比44%,其次是普惠公司,占比29%,劳斯莱斯和通用电气各占10%。

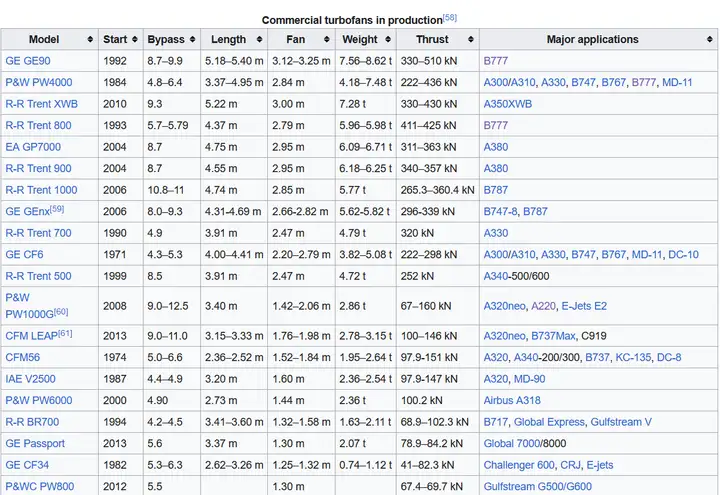

7.1 正在生产的商用涡轮风扇 | Commercial turbofans in production

8. 极高旁通比喷气发动机 | Extreme bypass jet engines

In the 1970s, Rolls-Royce/SNECMA tested a M45SD-02 turbofan fitted with variable-pitch fan blades to improve handling at ultralow fan pressure ratios and to provide thrust reverse down to zero aircraft speed. The engine was aimed at ultraquiet STOL aircraft operating from city-centre airports.

参考译文:在20世纪70年代,劳斯莱斯/斯奈克玛(Rolls-Royce/SNECMA)测试了一款搭载可变桨叶的M45SD-02涡扇发动机,以提高在超低风扇压力比下的操纵性,并能在飞机速度降至零时提供推力反向。该发动机主要用于在市中心机场运营的超静的短距离起降(STOL)飞机。

In a bid for increased efficiency with speed, a development of the turbofan and turboprop known as a propfan engine was created that had an unducted fan. The fan blades are situated outside of the duct, so that it appears like a turboprop with wide scimitar-like blades. Both General Electric and Pratt & Whitney/Allison demonstrated propfan engines in the 1980s. Excessive cabin noise and relatively cheap jet fuel prevented the engines being put into service. The Progress D-27 propfan, developed in the U.S.S.R., was the only propfan engine equipped on a production aircraft.

参考译文:为了提高速度和效率,涡扇发动机和涡桨发动机的一种改良型号被创建出来,这就是拥有无护罩风扇的螺旋桨发动机(propfan engine)。风扇叶片位于护罩之外,看起来像是带有宽大弯刀形状的涡桨发动机。通用电气和普拉特-惠特尼/爱立信在20世纪80年代展示了螺旋桨发动机的技术。然而,过高的机舱噪音和相对便宜的喷气燃料使得这种发动机没有投入使用。苏联研发的进步D-27螺旋桨发动机是唯一一种在生产飞机上配备的螺旋桨发动机。

9. 术语 | Terminology

Afterburner 加力燃烧室

- jetpipe equipped for afterburning[62]

参考译文:为加力燃烧而装备的喷射管[62]

Augmentor 扩增器

- afterburner for turbofan with burning in hot and cold flows[62]

参考译文:在冷热流中燃烧的涡轮风扇加力燃烧器[62]

Bypass 旁通

- that part of the engine as distinct from the core in terms of components and airflow, eg that part of fan blading (fan outer) and stators which pass bypass air, bypass duct, bypass nozzle

参考译文:在部件和气流方面与发动机核心不同的那部分,如风扇叶片(风扇外部)和定子通过旁通空气、旁通管道、旁通喷嘴的那部分

Bypass ratio 旁通比/涵道比

- bypass air mass flow /core air mass flow[63]

参考译文:旁通空气质量流量/核心空气质量流量[63]

Core 核心机

- that part of the engine as distinct from the bypass in terms of components and airflow, eg core cowl, core nozzle, core airflow and associated machinery, combustor and fuel system

参考译文:在部件和气流方面与旁通通道不同的那部分发动机,如核心整流罩、核心喷嘴、核心气流和相关机械、燃烧室和燃料系统

Core power 核心动力

- also known as “available energy” or “gas horsepower”. It is used to measure the theoretical (isentropic expansion) shaft work available from a gas generator or core by expanding hot, high pressure gas to ambient pressure. Since the power depends on the pressure and temperature of the gas (and the ambient pressure) a related figure of merit for thrust-producing engines is one which measures the thrust-producing potential from hot, high pressure gas and known as “stream thrust”. It is obtained by calculating the velocity obtained with isentropic expansion to atmospheric pressure. The significance of the thrust obtained appears when multiplied by the aircraft velocity to give the thrust work. The thrust work which is potentially available is far less than the gas horsepower due to the increasing waste in the exhaust kinetic energy with increasing pressure and temperature before expansion to atmospheric pressure. The two are related by the propulsive efficiency,[64] a measure of the energy wasted as a result of producing a force (ie thrust) in a fluid by increasing the speed (ie momentum) of the fluid.

参考译文:可用能量(也称为“气体马力”)是用于衡量气体发生器或核心的理论(等熵膨胀)轴功率,通过将高温高压气体膨胀至大气压力来获得。由于功率取决于气体的压力和温度(以及环境压力),衡量产生推力的发动机的相关指标是通过等熵膨胀到大气压力时计算得到的气流推力(stream thrust)。推力的重要性体现在乘以飞机速度以获得推力作业时。可用的推力作业远远小于气体马力,这是由于在膨胀至大气压力之前,排气动能随着压力和温度的增加而增加。这两者通过推进效率相关,推进效率是衡量在流体中通过增加流体速度(即动量)来产生力(即推力)而浪费的能量的度量。

Dry

- engine ratings/ throttle lever positions below afterburning selection

参考译文:发动机额定值/油门杆位置以下加力燃烧选择

EGT

- exhaust gas temperature

参考译文:废气温度

EPR

- engine pressure ratio

参考译文:发动机压力比

Fan 风扇

- turbofan LP compressor

参考译文:涡扇低压压缩机

Fanjet 涡扇飞机

- turbofan or aircraft powered by turbofan (colloquial)[65]

参考译文:涡轮风扇或由涡轮风扇驱动的飞机(口语)[65]

Fan pressure ratio 风机压力比

- fan outlet total pressure/fan inlet total pressure

参考译文:风机出口总压力/风机进口总压力

Flex temp 灵活温度

- At reduced take-off weights commercial aircraft can use reduced thrust which increases engine life and reduces maintenance costs. Flex temperature is a higher than actual outside air temperature (OAT) which is input to the engine monitoring computer to achieve the required reduced thrust (also known as “assumed temperature thrust reduction”).[66]

参考译文:在减小的起飞重量下,商用飞机可以使用减少的推力,从而增加发动机寿命并降低维护成本。灵活温度是高于实际外界温度(OAT)的温度,输入到发动机监控计算机中,以实现所需的减少推力(也称为“假定温度推力减少”)。

Gas generator 气体发生器

- that part of the engine core which provides the hot, high pressure gas for fan-driving turbines (turbofan), for propelling nozzles (turbojet), for propeller- and rotor-driving turbines (turboprop and turboshaft), for industrial and marine power turbines[67]

参考译文:发动机核心的这部分提供了燃料燃烧产生的高温高压气体,用于驱动风扇涡轮(涡扇发动机),用于推进喷嘴(喷气式发动机),用于驱动螺旋桨和旋翼的涡轮(涡桨发动机和涡轴发动机),以及工业和船舶动力涡轮。

HP 高压

- high-pressure 高压

Intake ram drag 进气闸板阻力

- Loss in momentum of engine stream tube from freestream to intake entrance, ie amount of energy imparted to air required to accelerate air from a stationary atmosphere to aircraft speed.

参考译文:发动机流管从自由流到进气口的动量损失,即将空气从静止大气加速到飞机速度所需的传递给空气的能量。

- integrated engine pressure ratio

参考译文:发动机综合压力比

IP 中压

- intermediate pressure

参考译文:中压

LP 低压

- low-pressure

参考译文:低压

Net thrust 净推力

- nozzle thrust in stationary air (gross thrust) – engine stream tube ram drag (loss in momentum from freestream to intake entrance, ie amount of energy imparted to air required to accelerate air from a stationary atmosphere to aircraft speed). This is the thrust acting on the airframe.

参考译文:推进喷嘴在静止空气中的推力(总推力)- 发动机气流管的气压阻力(从自由流到进气口的动量损失,即为将空气从静止大气加速到飞机速度所需的能量量)。这是作用在机身上的推力。

Overall pressure ratio 总压力比

- combustor inlet total pressure/intake delivery total pressure

参考译文:燃烧室进气总压力/进气输送总压力

Overall efficiency 总体效率

- thermal efficiency * propulsive efficiency

参考译文:热效率*推进效率

- propulsive power/rate of production of propulsive kinetic energy (maximum propulsive efficiency occurs when jet velocity equals flight velocity, which implies zero net thrust!)

参考译文:推进功率/推进动能的产生率(最大推进效率发生在喷射速度等于飞行速度时,这意味着净推力为零!)

Specific fuel consumption (SFC) 比燃油消耗量(SFC)

- total fuel flow/net thrust (proportional to flight velocity/overall thermal efficiency)

参考译文:总燃油流量/净推力(与飞行速度/总热效率成正比)

Spooling up 发动机快速增加转速直到达到正常运行速度的过程

- increase in RPM (colloquial)

参考译文:转速增加(口语化)

Stage loading